This assignment is to develop a User Requirements Specification for an electronic monitor and alarm system for an Oil Separator in Surface Water Drainage Systems.

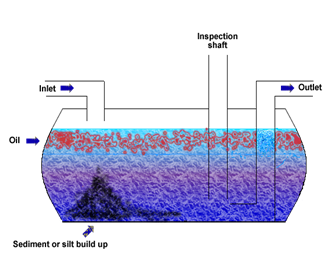

These separator systems are intended to take the surface water from a road. They will be buried in the ground and would take feeds from a number of grids located at the side of the road. The diagram below explains the principle.

Principle of an oil Separator for surface water drainage

The surface drainage water enters in through the inlet pipe and is dumped into the tank. The outlet pipe is taken from the base of the tank. Oil water mixture settles in the Separator, the oil will float to the surface to form a layer of oil residue. Sediment, such as soil, grit, rubber compound, etc. will be heavier than water and settle to the bottom of the tank. As the inlet fluid fills up so clean water will be discharged to a land drain. It is important that:

- The oil layer does not get to thick so that it can bypass the physical separation barrier and thus pollute the land drain.

- The Separator fills up with sediment and blocks the outlet rendering the Separator system ineffective.

An inspection shaft is included in the design so that the Separator can be pumped clean into a tanker lorry. This can also be used to mount sensors to determine:

- That the oil layer does not exceed the maximum permitted value.

- That the sediment has not risen above maximum permitted value.

As petroleum products will be present in the separator there is risk of an explosion occurring within the separator or its locality.

The separators will often be located some distance from wired main electrical supplies so will have to operate on a battery system that perhaps can be supported by solar and wind power.

A warning system has to be provided, to enable the governing authority to develop a cost effective management strategy separator maintenance for the groups of separators. The electronic monitor and alarm system will provide alarms locally and remotely, to:

- Give both an indication of the type of alarm occurring, oil or silt, audible and visual.

- A local reset of the audio alarm.

- A test facility for the monitor and alarm system.

The oil level sensor should be fitted into the separator so that the sensor is 50-100mm below the normal level with in the interceptor as shown in the diagram below. This will enable the device to measure the height of the layer of oil.