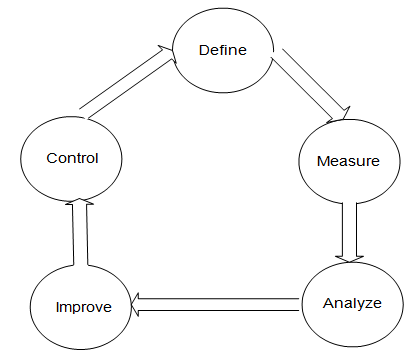

DMAIC process

DMAIC was introduced by Motorola to help improve the business processes and also to increase the profitability. It can be defined both as a methodology and a business management strategy used for the metric measurement of the defects. DMAIC is a five step improvement process and stands for Define, Measure, and Analyse. Improve and Control.

Figure DMAIC process

DMAIC steps and goals of each phase are as follows:

Define - Define is the first phase of the DMAIC process. The aim of the define phase is to clearly recognise and communicate the problem in a clear and measurable way. The basic steps in the define phase of the DMAIC are as follows:

- Recognising or refining the problems in the process which must be solved in order to meet or exceed the customer's specifications or expectations.

- Recognising and quantifying the customer requirements.

- Recognising and quantifying the process output and defects which donot comply with the requirements and also create a problem statement.

- Stating a clear and measurable the project goal and also include a time limit for the project's completion.

- Determining the few important factors that are critical to quality which needs to be measured, analysed, improved and controlled.

- Creating a project charter which will have the problem definition, goal, business case, project scope, team members and high level project plan for the M,A,I and C phases of DMAIC process.

Measure - Measure phase in the second phase in DMAIC process and is dedicated to assembling the data collection plan, executing that plan and also verifying if the data collection is performing properly. To execute the measure phase the team must:

- Select the critical to quality characteristics in the process. The output of the given process is important to the customer.

- Define what the process output should be, which can be done by looking at the customer requirements and also at the project goals.

- Define the process defect (Defect is an output which falls outside the limits of the customer's requirements or expectations which can be measured).

- Measure the defects which can affect the critical to quality characteristics as well as any other related factors.

- Incorporate the measurement system analysis which is a method to make sure that the defects are being measured properly.

- Refine the data collection procedures.

The sigma level for the process can be calculated once the defects have been measured and used as a baseline to compare against the improved process. Once the defects have been measured and all the critical data has been collected, the cause for problems have to be found out which means that the inputs given to the process and the parts of the process which are affecting the output should be found out.

Analyse - Analyse is the third phase of the DMAIC process. In this the team sets out to recognise the root cause of the problem. But, unlike the other problem solving strategies the DMAIC needs that the root cause be validated by the data. There are many root cause analysis method which can be used in the analysis phase which includes the Brainstorming, 5

Whys and Fishbone diagram which is also known as the Cause and Effect diagram. As with most of the root cause tools the team must utilise the process map, the collected process data and also the other accumulated knowledge during define and measure phase which will help to arrive at the root cause.

The main feature of the Analyse phase is the statistical analysis which is conducted. The Six Sigma professionals generally will look for the statistically important event which can be acted upon. It is this higher level of analysis which sets the Six Sigma apart from the lower level problem solving strategies. Before implementing Six Sigma, the team should be assured that the chosen solution actually works. The pilot programs, computer simulations and the segmented implementation are all possible at this point. Once the process metrics have been captured, analysis tools can be used to understand where the process is failing to meet the performance specifications or where the unexpected activity is happening.

In the analyses phase first the hypotheses of the defects cause has to be developed and then the data has to be analysed and the process with the help of statistical and non-statistical methods.

Improve - Improve is the fourth step in the DMAIC process and it is the point where the hard work of the defining, measuring and analysing and where the ideas for the process improvement are formulated and also implemented. The main objective of the improve phase of DMAIC is to determine the solution to the problem at hand. The potential solutions are generated using Brainstorming. It is good to include the people who perform the process regularly. The input to the solution created can be invaluable and may also give the best possible solution ideas because of the process knowledge. The best overall solution should be found out by the team. A solution criteria list is another tool used to assist in choosing the best solution.