Distortion energy theory:

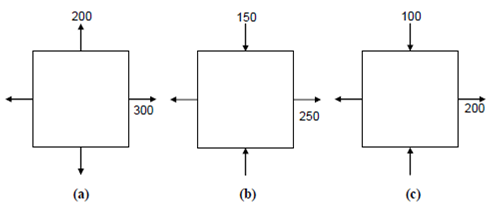

Let us now consider the solid shown in Figure.

(a) By inspection we may see that the solid is safe according to principal stress theory (σ1 < 260).

(b) Maximum principal strain ε1 = 200/E -0.3 (-100/E) = 230/E < 260/E

∴ The solid is safe according to principal strain theory too.

(c) Maximum shear stress τmax =200- (-100)/2 =150>130

∴ Shear stress theory predicts failure.

(d) Total strain energy density is as follows :

u = 1/2E [2002 + (- 100)2 - 2 × 0.3 ×200 (- 100)]

=31000/E > 2602/E

∴ The solid is safe according to strain energy theory.

(e) Distortion energy density is as follows:

ud = 1/12G([200 - (- 100)]2 + 2002 + 1002 )

70000/6G > 2602/6G

∴ Distortion energy theory predicts failure.

If what is safe according to one theory is unsafe according to the other theory although what is safe according to the second theory is unsafe according to while another theory, you might wonder whether to consider the solid as safe or not. Or should the solid be safe according to all the theories? That will put a extremely severe condition for safety. Shall we select a theory which we like best? Certainly not, we have to search out which theory correctly represents the failure criteria and choose it. It has been found from experience in which the shear stress theory (known as Tresca's Theory) suits brittle materials, although, the distortion energy theory (known as Von Mises' Theory) is appropriate for ductile materials. So depending on the nature of the material, the designer could choose the appropriate theory.

You might also remember, that it is not sufficient to be merely safe (irrespective of the theory), but that there should be a enough margin of safety, defined through the Factor of Safety selected depending on the nature of the problem.