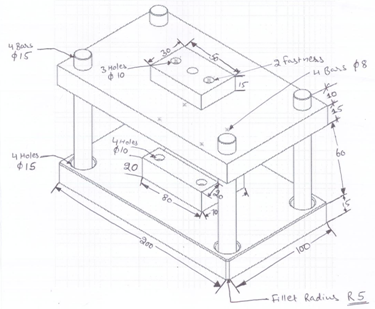

Die Press Assembly Drawing

The objective of this assignment is to demonstrate the following concepts of design.

• Extrude

• Revolve

• Fillet

• Dimensioning

• Tolerance

• Basic shaping processes

• Basic joining processes

• Basic modeling and sketching techniques

Tasks that need to be done:

1. Report

Write a report about the concepts of mechanics in Section 1(a) of report. Your report should include a brief introduction and summary, as well as a list of references. Marks will be allocated for proper formatting, including these elements:-

- Report must have introduction, section headers and summary

- Pages of the report must be properly numbered

- Report must include a table of contents

- All figures and tables must be properly labeled and referenced in the text

- Properly citing sources of information using the Harvard Name System of Referencing

- Report should be written in about 2500 words

(a) Explain the concepts of design listed below and describe it in the form of a statement.

• Extrude

• Revolve

• Fillet

• Dimensioning

• Tolerance

• Basic shaping processes

• Basic joining processes

• Basic modeling and sketching techniques

(b) Perform a simple practical work in laboratory on design software which helps you to demonstrate the algorithm for Die Press Assembly Drawing as shown below.

(i) Write the algorithm for the drawing.

(ii) Draw 2D drawing with proper dimensioning

(iii) Draw 3D drawing with proper dimensioning

(iv) Assembly drawing with proper dimensioning.

Die Press Assembly Drawing

Note: - All dimensions are in mm

2. Demonstration

Describe and demonstrate the experiment which you have performed in front of your class.

Note: Student has to submit hard copy & soft copy of report in the form of CD also.