Determine the maximum bending moment:

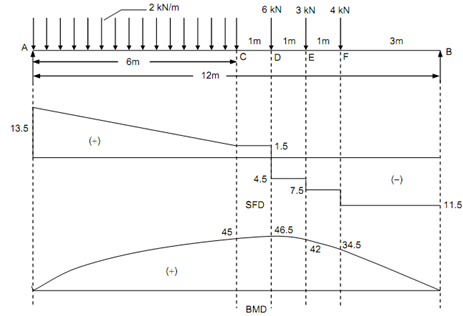

A 12 m span simply supported beam is carrying a consistently distributed load of 2 kN/m over a length of 6 m from the left end and point loads 6 kN, 3 kN and 4 kN at distances of 7 m, 8 m and 9 m, respectively. Draw BM diagram and SF diagram for the beam and determine the maximum bending moment.

Figure

Solution

Taking moments around A, and equating to zero.

RB × 12 - (4 × 9) - (3 × 8) - (6 × 7) - 2 × 6 ×(6/2) = 0

Therefore, RB = 11.5 kN, and

RA = (2 × 6) + 6 + 3 + 4 - RB = 25 - 11.5 = 13.5 kN

Shear Force (beginning from the left end)

SF at A, FA = + 13.5 kN

SF at C, FC = + 13.5 - 2 × 6 = + 1.5 kN

SF just left of D = + 1.5 kN

SF just right of D = + 1.5 - 6 = - 4.5 kN

SF just left of E = - 4.5 kN

SF just right of E = - 4.5 - 3 = - 7.5 kN

SF just left of F = - 7.5 kN

SF just right of F = - 7.5 - 4 = - 11.5 kN

SF just left of B = - 11.5 kN = Reaction at B.

Bending Moment

BM at A, MA = 0

BM at C, M = (13.5 × 6) - 2 × (6 ×(6/2)) = 45 kNm (considering left side)

BM at D, MD = (11.5× 5) - (4 × 2) - (3 × 1) = 46.5 kN m (considering right side)

BM at E,

ME = (11.5 × 4) - (4 × 1) = 42 kN m

BM at F,

MF = (11.5 × 3) = 34.5 kN m

The maximum bending moment take place at D where the shear force changes sign.

Mmax = 46.5 kN m.