Determine the final stresses in the bolt:

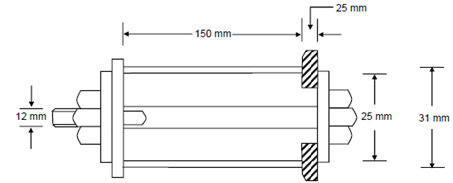

A steel bolt of diameter 12 mm and length 175 mm is used to clamp a brass sleeve of length 150 mm to a rigid base plate as in Figure. The sleeve has an internal diameter of 25 mm and a wall thickness of 3 mm. The thickness of the base plate is 25 mm. Initially, the nut is tightened until there is tensile force of 5 kN in the bolt. The temperature is now increased by 100°C. Determine the final stresses in the bolt and the sleeve.

For computation purposes, take following values:

Eb = 105 GNm-2 ; Es = 210 GNm-2

αb = 20 × 10 -6 K-1 ; αs = 12 × 10 -6 K-1

Figure

Solution

Let the free thermal expansions of steel and brass be Δs and Δb and Δ be the common expansion. Then

Δs = (175) (12 × 10-6) (100) = 0.21 mm

Δb = (150) (22 × 10-6) (100) = 0.3 mm

If the initial stresses in steel and brass due to 5 kN load are σs1 and σb1, then

σs1 = +( 5 × 103 × 4)/π (12)2 = + 44.21 N/mm2 (Tensile)

σb1 = +( 5 × 103 × 4)/π (312 - 252) = + 44.21 N/mm2 (Compressive)

Equilibrium of thermal stresses σs2 and σb2 requires that

σs2 × π (12)2/4 +σb2 × π (312 - 252 )/4 = 0

or 3 σs2 + 7 σb2 = 0

The thermal strains are given by

εs = (Δ- Δs )/175 and εb = (Δ- Δb )/150

Thus, the thermal stresses are as follows:

σs2 = 210/175 (Δ- Δs) × 103 N/mm2

and σb2 = 105/150 (Δ- Δb) × 103 N/mm2

Substituting these in the equilibrium equation,

3 × 210/175 (Δ - 0.21) × 103 + 7 × 105/150 (Δ - 0.30) × 103 = 0

Hence, Δ = 0.262 mm

Thus,

σs2 = 210/175 (0.262- 0.21) × 103 = + 62.26 N/mm2 (Tensile)

σb2 = 105/150 (0.262- 0.3) × 103 = - 26.28 N/mm2 (Compressive)

Total stresses are therefore as follows:

σs = σs1 + σs2 = - 106.5 N/mm2 (Tensile)

σb = σb1 + σb2 = - 4.56 N/mm2 (Compressive)