Determine ratio between mass flow rate to condensing steam:

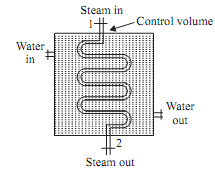

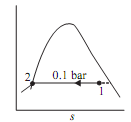

In steam power plant, the steam 0.1 bar and 0.95 dry enters condenser and leaves as saturated liquid at 0.1 bar and 45°C. Cooling water enters condenser in separate steam at 20°C and leaves at 35°C without any loss of its pressure and with no phase change. Neglecting heat interaction between condenser and surroundings and changes in kinetic energy and potential energy, determine ratio between mass flow rate of cooling water to condensing steam.

Sol.: Given that:

Inlet condition of steam: Pressure 'P1' = 0.1 bar dryness fraction x = 0.95 The exit condition of steam saturated water at 0.1 bar and 45°C Inlet temperature of cooling water = 20°C Exit temperature of cooling water = 35°C Applying SFEE to control volume Q - Ws = mf [(h2 - h1)+ ½(V22 - V12) + g(z2 - z1)]

Figure

neglecting changes in kinetic and potential energies. And there is no shaft work that is.; Ws = 0

Q = mf (h2 - h1)

h1 = hf1 + xhfg1

= 191.81 + 0.95 (2392.82) = 2464.99 kJ/kg

h2 = hf2 at 0. 1 bar (as the water is saturated liquid)

h2 = 191.81 kJ/kg

Q = mf (191.81 - 2464.99)

= - 2273.18mf kJ/kg ...(i)

negative sign shows the heat rejection.

By energy balance; Heat lost by steam = Heat gained by cooling water

Q = mfw.Cw (T4 - T3) = mfw x 4.1868(35 - 20) = 62.802mfw ...(ii)

Equate equation (i) and (ii); We get Q = -2273.18mf = 62.802mfwmfw/mf = 36.19 Ratio of mass flow rate of cooling water to the condensing steam = mfw/mf = 36.19