Heat Transfer Coursework

An internal combustion engine of a passenger car is operating at steady state conditions e.g. constant speed (r.p.m.) and load (torque), so the engine exhaust gas temperature will remain constant during the time of the operation at each location. The exhaust gas flow in the car exhaust pipe is 250 kg/h. A catalyst has been located in the exhaust pipe in order to reduce the pollutants generated during the combustion process. It has been observed that the catalysts optimum operational temperature is around 250oC. Too high temperature (>600oC) may damage the catalyst and too low temperatures (<200oC) will affects its efficiency in reducing pollutants.

Thermocouples cannot be placed inside the exhaust pipe in order to measure the axial temperature gradient of the exhaust gas as that will affects the exhaust flow characteristics.

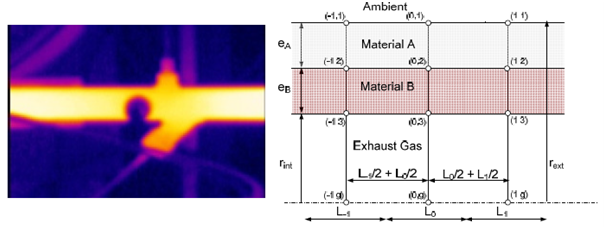

Therefore, a non-intrusive method (thermographic camera) is used to measure the surface temperature of the external diameter of the exhaust pipe in three different axial locations (-1, 0 and 1).

1. Define the heat transfer processes in the exhaust pipe and draw a schematic of the equivalent 'resistance' system. Calculate the different types of resistances of the system.

[Hint: Consider radial and axial heat flux and neglect radiation].

Figure: Schematic of the exhaust pipe, picture on the left taken with the thermographic camera, schematic on the right

2. In which location along the exhaust pipe will you place the catalyst in order to achieve its optimal operation temperature of ~ 250ºC.

[Hints: Calculate the gas properties required and estimate the heat transfer coefficient, h, by assuming that the engine exhaust gas has similar properties to air at constant temperature of 250ºC. Use the Dittus-Boelter correlation to estimate the heat transfer coefficient].

3. Calculate the exhaust gas temperature (e.g. in the three different locations) assuming only radial heat transfer. Compare and justify the results with respect to the case above in point 2 where radial and axial heat transfer were considered.

Onwards for the points 4 and 5 below assume only radial heat transfer flux (neglect axial heat transfer).

4. For safety reasons the exhaust temperature of the pipe (423.15K) measured at point (0, 1) needs to be reduced. Can this be achieved by changing the order of the materials A and B?

Please justify your answer.

5. For the original exhaust pipe configuration (i.e. material B closer to the exhaust gas) consider that there are exothermic chemical reactions at point (0, g) where the catalyst has been introduced in the exhaust pipe. As a result the exhaust gas temperature at this point has increased by 100ºC. Calculate the temperature recorded by the thermographic camera at that position (0, 1)?

6. For the above case (point 5) obtain the maximum allowed thermal conductivity of a new material which could be used to replace one of the previous materials in order to keep the exhaust pipe temperature at point (0, 1) lower than 423.15K.

[Note: The thickness of each material cannot be modified, while you can modify the order of the materials].