Define Recommendations for Design of PTFE Sliding Bearing?

Other Recommendations for Design of PTFE Sliding Bearing

1. Expansion bearings having sliding surfaces of PTFE shall have a provision for minimum 0.01 radians of rotation. This is to prevent excessive local stresses on the PTFE sliding surface.

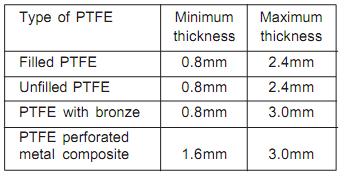

2. The minimum and maximum thicknesss of PTFE sliding surface shall be as given in Table.

Table: Thickness of PTFE Surfaces

3. The contact surface of PTFE shall have a minimum Brinell hardness of 125 and surface finish of less than 20 microns.

4. Holes or slots shall not be made in the sliding surfaces.

5. For calculating the pressure on PTFE, the contact surface area may be taken as the gross area of the PTFE without making any deduction for lubricating cavities, if any.

6. The stresses in the elastomer are limited by the effectiveness of the seal preventing it from squeezing out. However, they should not exceed 40 N/mm2.

7. The lateral pressure exerted on the cylinder (POT) can be considered to be that produced by the pad acting as a fluid. The stress analysis in the pot is very complex and should be verified by testing.