Computer added design

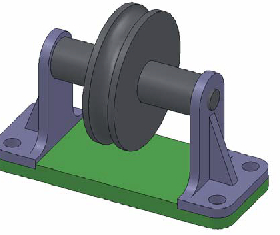

Using SolidWorks create an assembly model of the roller, bracket and base shown to the right. The assembly is also shown in exploded view below. You may choose whatever dimensions (to the nearest mm) you like, except for the distance between hole centres for the brackets, as long as it looks similar to the model shown here. The dimension for the hole centres is based on the alpha numeric value (A=1, Z=26) of the initial of your surname. The hole centre distance should be

√i ×100 (rounded to the nearest 10 mm) where

i is the alpha numeric value of your initial. E.g. if your surname is Brown, the dimension between hole centres will be √2 ×100 × 141 =>140mm. Your part models must capture the correct design intent, i.e. symmetry of parts, axial alignment of cylindrical parts, axle hole concentric with bracket top round. For example, if I change a dimension of one of your parts, the width of the bracket say, I should not have to change any other dimension to restore symmetry to the part. If your model does not do this it will lose marks.

Your assembly model should be properly constrained by using appropriate mates. I should be able to change a dimension, the height of the base say, and the rest of the parts should move to the correct locations without further manipulation (except perhaps to "Rebuild" the model). You do not need to have the dimensions of the individual parts dependent on each other although you may do this if you wish/can. For example, if you change the width of the base, it is not necessary (for the purposes of the assignment) to have the width of the bracket automatically update to match it.

Create the following drawings from your solid and assembly models:

1. three orthographic views and an isometric view showing of the bracket part. The orthographic views should be properly dimensioned following the guidelines discussed in lectures.

2. an isometric assembly drawing and an exploded assembly drawing of the Roller assembly. This drawing should also contain a Bill of Materials.

If you work together with others you must create your own models and ensure that your dimensions are different from theirs. Any two or more submissions that have identical dimensions will be considered to be copied and will receive no marks.