Assigned homework

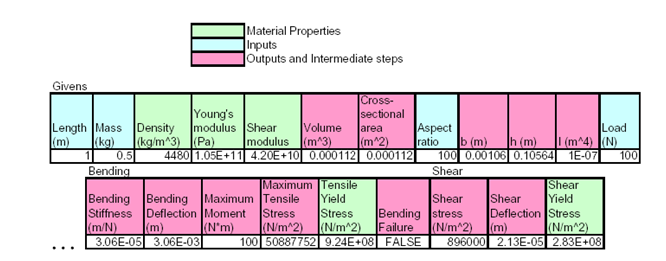

a. The objective of this problem is to get a sense of the tradeoff between cross-section and stiffness for beam structural member. Consider a beam that is 1 meter long and is allowed no more than 0.5 kg mass. For this exercise we will use Aluminum 2024-T3, with the following properties.

Density: 2780 kg/m^3

Young's Modulus: 73.1 GPa

Shear Modulus: 28 GPa

Tensile Yield Stress: 345 MPa

Shear Yield Stress: 283 MPa

Using Excel, and the relationships described in lecture for beams, create a worksheet which allows you to answer the following questions. The worksheet will likely have the following columns.

1. Given the density, length, and total mass of the aluminum beam, what is the volume of aluminum available, and what is the cross-sectional area?

2. The allowable area can be distributed in any shape we want. For this exercise we will consider only rectangular cross-sections. Although area is fixed by the beam mass, we can vary the aspect ratio to get different base and height dimensions. What are the equations for h and b in terms of A and aspect ratio r?

3. For the cases of aspect ratio 100, 10, 1, 0.1, 0.01, what are the moments of inertia of the resulting cross-sections, the bending deflection, and the maximum stress due to bending?

4. For which aspect ratios does the bending stress exceed yield stress of the beam?

5. How much greater is the bending deflection than the shear deflection for the aspect ratio = 1 case?

b. Discuss / compare the factors needed to consider to accurately compute the wheel load of various transportation devices, starting with a unicycle, then a segway, tricycle, grocery shopping cart, an automobile and then a tank tread. Describe how it becomes increasingly difficult to accurately determine the wheel load and the factors needed to be considered to overcome those difficulties.