Compute depth of yielding in the hollow shaft:

A solid shaft 80 mm diameter is solid for a certain length from one end but hollow for the remaining length along inner diameter of 40 mm. If a pure torsion is applied such that yielding occur at the surface of the solid part of the shaft. Compute:

(1) the depth of yielding in the hollow shaft, and

(2) the ratio of the angles of twist per unit length.

Solution

τ = Shear stress at yield point.

Torsion in the solid shaft =τ × ( π× 803 /16)

T1 =τ × (π× 803 /16) ------------- (1)

For Hollow Shaft

Torsion in the unyielded part

T2 =τ × (π/16 D) (D 4 - 404) ----------- (2)

where D = diameter of the hollow section at which yielding begins.

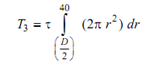

Torsion in yielded part

= (πτ /12 )(803 - D3 ) -------------- (3)

T1 = T2 + T3

⇒ 803/16 = D4 - 404/16 D + (803 - D3/12)

⇒ 12 × 803 D = ( D4 - 404 ) 12 + 16 D (803 - D3 )

⇒ 6144 × 103 D = 12D4 - 3072 × 104 + 8192 × 103 D - 16 D4

⇒ 4D4 - 2048 × 103 D + 3072 × 104 = 0

⇒ D 4 - 512 × 103 D + 768 × 104 = 0 ----------- (4)

By trial and error, D = 74.8 mm

T / J = τ/ R = G θ/ l

⇒ θ= τl /GR ---------- (5)

θS =2τl / (G × 80) ------ (6)

θH = 2τl / (G × D) --------- (7)

θH/ θS = 80/ D = 80/74.5 = 1.07