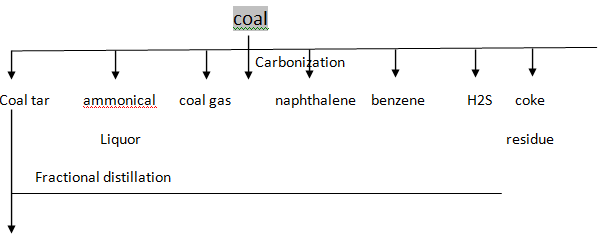

When coal is heated strongly in absence of air, it forms a strong, porous, dense and coherent mass known as coke. This process of conversion of coal into coke is called carbonzation.

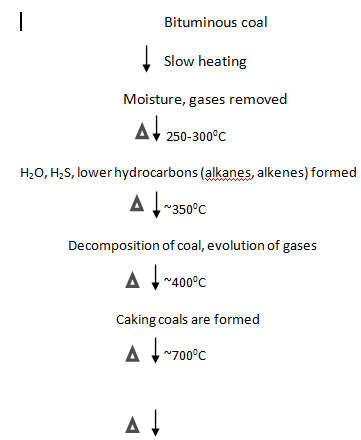

(Note: The coal on carbonization becomes soft, plastic and fuse together to a large coherent mass, they are called caking coals. Such coals are difficult to be oxidized. If the coke obtained is porous, hard, strong and usable for metallurgical purposes, then the coal is known as coking coal.)

Steps involved in carbonization process

Hydrogen is eliminated

~8000C

Formation of plastic mass, evolution of gases

9000C

Coke is formed by

Solidification of plastron, foam like mass

There are two types of carbonization.

1. Low temperature carbonization.

2. High temperature carbonization.

1.11.1 Low temperature carbonization

When the carbonization is carried out at 500-7000C, that it is called low temperature carbonzation. The coke contains 5-15% volatile matter and cannot be used for metallurgical processes. It ignites easily and is used in domestic usages. Coke obtained is smokeless and the byproduct gas obtained has high calorific value (6500-9500kcal/m3).

1.11.2 High temperature carbonization

When carbonization is carried out at 900-12000C, it is called high temperature carbonization. The coke produced has high strength, purity, hardness, desired porosity, and is used for metallurgical purposes. Coke obtained has low volatile matter (1 - 3 %) and the byproduct gas obtained has low calorific value (5400-6000 (kcal/m3).