Question:1

(a) A flowchart of a continuous steady state two-unit separation process is shown below (Figure 1.1). Each stream contains two components, x and y, in different proportions. Four streams whose flow rates and compositions are not known are labelled A, B, C and D. Calculate the unknown flow rates and compositions of streams A, B, C and D.

(b) In a continuous bread oven, the hot air must contain at least 5% (weight percent) water to prevent the crust of the dough from drying too rapidly resulting in both reduced dough expansion and moisture loss from the bread centre. The original fresh air feed contains 1% water. 1250 kg hr-1 of dough is baked. During the baking process the water content is reduced from 36% to 29% (weight percent). The wet air leaving the oven contains 8.5% water. The flowchart for the process is shown in Figure 1.2. All water compositions are given as weight percent. The dough/bread can be assumed to consist of solids and water, and air is made up of dry air and water.

(i) Calculate the flow rate of bread produced.

(ii) Determine the flow rate of makeup air and recycled wet air required.

Question 2

A food product made of corn grits is extruded.

During the extrusion process work and heat are added to the corn grits as they travel down the extruder barrel. The work comes from the motor and the heat is added via an electrical heating element. The pressure and temperature of the extruder barrel are measured, just before the product leaves the barrel, and are found to be 5 MPa and 200°C respectively. The grits enter the other end of the extruder at atmospheric pressure and 20°C.

It is found that operating the extruder for 10 minutes uses a total of 50 kg of raw materials, and the motor consumes 10,000 kJ of energy. Assume that the extruder is 70% efficient in converting the motor energy into useful work (that is transferred to the product).

The corn grits are 12% water and assume that the specific heat capacity of the remaining material is constant at 2000 J (kg K)-1.

(a) Calculate the amount of heat added to the corn grits, by the electrical heaters, over the 10 minute period.

(b) When the extrudate leaves the extruder barrel, some fraction of the water flashes to steam (because the pressure outside the extruder barrel is only atmospheric). This causes the food product to expand and puff, as it leaves the extruder.

(iii) Calculate the amount of water that flashes to steam, for every kg of water in the raw material.

(iv) What is the moisture content of the final product?

The final moisture content is meant to be 5%:

(v) What temperature should the product be heated to by the end of the extruder to ensure this (assume that the pressure is fixed at 5 MPa)?

(vi) How much additional heating or cooling needs to be done in the extruder barrel to achieve this (in kW, assuming the same mass flow rate of product)?

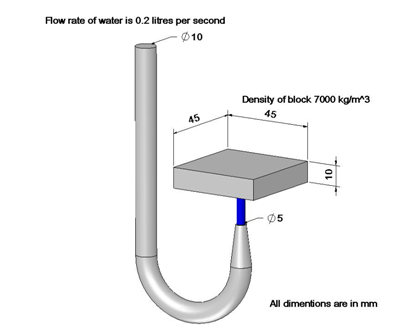

Figure shows a 10 mm diameter pipe with a 180° bend ending in a nozzle with an exit diameter of 5 mm. When water flows out of the nozzle it travels vertically upwards, loosing velocity with height until it hits a metal plate suspended above the nozzle. Given that the volumetric flow rate of water is 0.2 L.s-1 calculate the following:

(a) The mass flow rate and velocity of the water in the 10 mm diameter pipe and coming out of the 5 mm diameter nozzle.

(b) The pressure at the start of the nozzle.

(c) The force required to be exerted on the bend in order to hold the pipe stationary, where the weight of the water and pipe work comes to 0.06 kg and that the pressure going into the bend is the same as that going into the nozzle: i.e. neglect friction effects in the bend and the nozzle. (If you do not have an answer for part (b), then use P1 = 50 kPa.)

(d) How high the plate will be held above the top of the nozzle by the force of the water jet hitting it underneath. The plate above the nozzle is made of a material with a density of 7000 kg.m-3.