Calculate stress intensity factor:

For the plate in Figure (a) W = 25 mm, 2a = 10 mm, plate thickness, t = 2 mm, Load P = 1000 N. Calculate stress intensity factor if length of plate is 150 mm.

Solution

For crack at a distance of 75 mm from loaded end, the effect of edge on SIF may be disregarded.

SIF may be calculated from Eq. (3).

s = P/ Wt = 1000 /25 ´2 = 20 N/mm2

P a / W = P´5/25 = 0.6284

∴ tan P a /W = tan 0.6284= 0.7265 (Note P a/W is in radians)

∴ K I = s[W tan P a / W]1/2 = 20[25´0.7256]1/2

or, K I = 85.235 N/mm2 (  ) ---------- (i)

) ---------- (i)

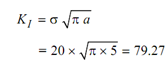

If a/W = 5/25=1/5 is regarded as small, then

-----------(ii)

-----------(ii)

(i) and (ii) are only approximately close.