Calculate strength coefficient:

A copper specimen of 64 mm gauge length and 12.80 mm dia. was tested in tension. Following two diameters were recorded in the plastic range of deformation.

Load = 25.75 kN, d1 = 12.176 mm

Load = 24.25 kN, d2 = 8.581 mm

Calculate strength coefficient and strain hardening exponent.

Solution

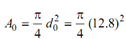

Original area of cross-section,

A0 = 128.6144 mm2

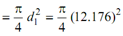

Area of cross-section at 25.75 kN

A1 = 116.3802 mm2

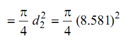

Area of cross-section at 24.25 kn

A2 = 57.8023 mm2

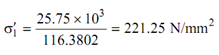

∴ True stress at 25.75 kN,

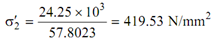

True stress at 24.25 kN,

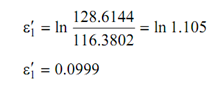

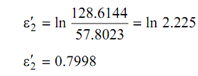

Note from Eq. (1.15) true strain ε′ = ln A0

And

Thus two pairs of values are obtained. Use these values of σ′ and ε′ in Eq. (1.15), i.e. ln σ′ = ln k + n ln ε′

∴ ln 221.25 = ln k + n ln 0.0999 and

ln 419.53 = ln k + n ln 0.7998

Subtract first equation from second

6.039 - 5.399 = n (- 0.2234) - n (- 2.3036)

i.e. 0.64 = 2.0802 n

or, n = 0.64 /2.0802= 0.3077 ------------ (i)

Using this value in one of above equations

5.399 = ln k + 0.3077 (- 2.3036)

∴ ln k = 5.399 + 0.7088 = 6.1078

k = 449.35 N/mm2 ---------------- (ii)

∴ True stress-true strain relationship for copper is

σ′ = 449.35 ε′0.3077 ------------(iii)