Calculate force required for equilibrium:

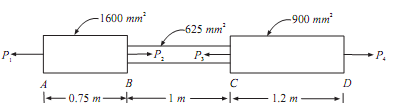

A member ABCD is subjected to the point loads P1, P2, P3 and P4 as shown in the figure given below

Calculate force P3 required for equilibrium if P1 = 120 kN, P2 = 220 kN and P4 = 160 kN. Determine the net change in length of member. Take E = 200 GN/m2.

Sol.: Modulus of elasticity E = 200 GN/ m2 = 2 × 105 N/mm2.

By considering equilibrium of forces along axis of the member.

P1 + P3 = P2 + P4;

120 + P3 = 220 + 160

Force P3 = 220 + 160 - 120 = 260 kN

The forces which are acting on each segment of member are shown in free body diagrams shown below:

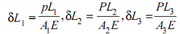

Let δL1, δL2 and δL3, be extensions in parts 1, 2 and 3 of steel bar respectively. Then,

As, Tension in AB and CD but compression in BC,

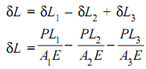

So, Total extension of the bar,

Extension of segment AB = [(120 × 103) × (0.75 × 103)]/[1600 × (2 × 105)] = 0.28125 mm

Compression of segment BC = [(100 ×103) × (1 × 103)]/[625 × (2 × 105)] = 0.8 mm

Extension of segment CD = [(160 ×103) × (1.2 × 103)]/[900 × (2 × 105)] = 1.0667 mm

Net change in length of the member = δl =0.28125 - 0.8 + 1.0667 = 0.54795 mm (increase) .......ANS