BURNERS :

ATOMISER BURNERS

This type of burner presents the fuel in a finely atomised spray by forcing the fuel to pass through a small orifice. The size of the orifice is critical because it must atomise the fuel effectively over a wide range of fuel flows, from idling to take off RPM.

Some engines have such a wide range of fuel flow requirements that a single orifice is unable to perform the task effectively unless extremely high fuel pressures are used and to combat this a burner with two different sized orifices are used. During low fuel flow requirements, only the small or primary orifice is supplied with fuel and at higher flow rates both primary and secondary orifices are in operation.

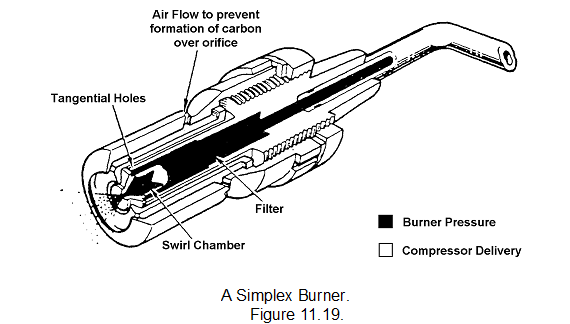

Both types of atomiser burners incorporate an air shroud, which directs some of the primary air into the burner to assist atomisation and to cool the burner head to prevent the formation of carbon.

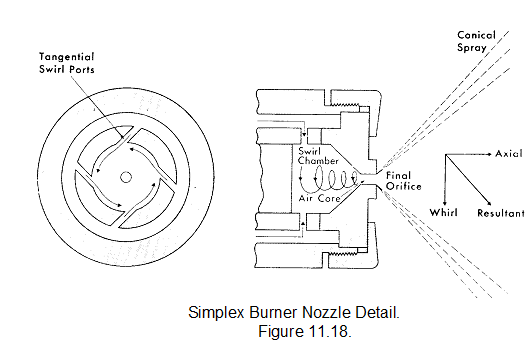

The usual method of atomising the fuel is to pass it through a swirl chamber where tangentially disposed holes or slots impart swirl to the fuel by converging its pressure energy to kinetic energy. In this state, the fuel passes through the discharge orifice where the swirl motion is removed as the fuel atomises to form a cone-shaped spray. The shape of the spray is an important indication of the degree of atomisation; thus, the rate of swirl and therefore the pressure of the fuel at the burner are important factors in good atomisation.

The simplex burner

The Simplex burner shown in the figure. was first used on early jet engines. It consists of a chamber, which induces a swirl into the fuel and a fixed area atomising orifice. This burner gave good atomisation at the higher fuel flows, that is at the higher burner pressures, but was very unsatisfactory at the low pressures required at low engine speeds and especially at high altitudes. The reason for this is that the Simplex burner was by the nature of its design a "square law" burner, that is the flow through the burner is proportional to the square of the pressure drop across it. This meant that if the minimum pressure for effective atomisation was 30 lbf/in2, the pressure needed to give maximum flow would be about 3,000 lb/in2.

The Duplex burner.

The Duplex burner or Duple burner require a primary and a main fuel manifold and have two independent orifices, one much smaller than the other. The smaller orifice handles the lower flows and the larger orifice deals with the higher flows as the burner pressure increases. A pressurising valve may be employed with this type of burner to apportion the fuel to the manifolds (see figure 11.20.). As the fuel flow and pressure increase, the pressurising valve moves to progressively admit fuel to the main manifold and the main orifices. This gives combined flow down both manifolds. In this way, the Duplex and the Duple burner are able to give effective atomisation over a wider flow range than the Simplex burner for the same maximum burner pressure. Also, efficient atomisation is obtained at the low flows that may be required at high altitude. In the combined acceleration and speed control system the fuel flow to the burners is apportioned in the FFR.

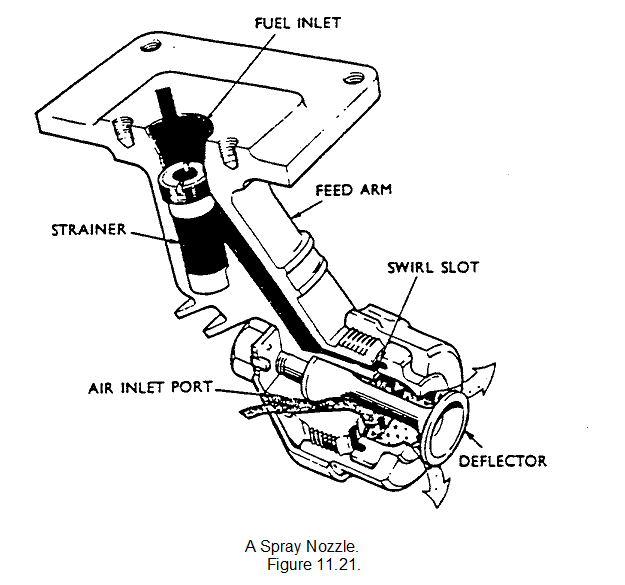

The Spray nozzle.

The spray nozzle carried a proportion of the primary combustion air with the injected fuel. By aerating the spray, the local fuel-rich concentrations produced by other types of burner are avoided, thus giving a reduction in both carbon formation and exhaust smoke. An additional advantage of the spray nozzle is that the low pressures required for atomisation of the fuel permits the use of the comparatively lighter gear-type pump.

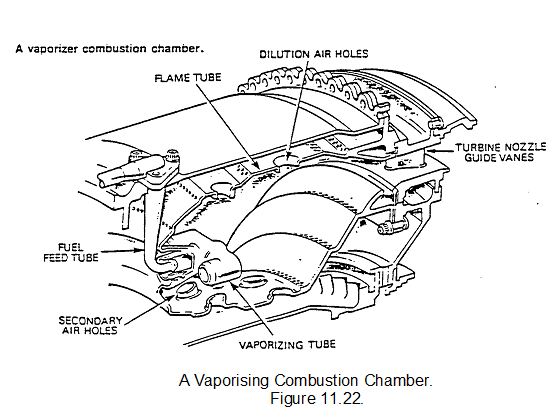

VAPORISING BURNERS

This type of burner presents the fuel in the combustion system in the form of a rich fuel vapour or gas. This is achieved by delivering the metered flow of fuel to "J" shaped vaporising tubes, which protrude into the combustion chamber. The fuel passes down the vaporising tubes in a coarse spray and mixes with the primary air that enters concentrically to the fuel supply pipe. The fuel and air is mixed thoroughly by pins that protrude into the primary airflow and the heat of the flame surrounding the tube causes the mixture to vaporise before it emerges in the combustion chamber.

The introduction of the primary air into the vaporising tubes aids the process of vaporisation and also helps to cool the tubes to prevent the formation of carbon.

With this type of burner, the flame points towards the incoming airflow and this helps to stabilise the flame in the vaporising tubes, preventing it being blown away by the secondary air, thus allowing a relatively short combustion system.

The advantages of this type are:-

a) Pre-vaporising gives complete combustion within a short length of flame tube.

b) A complete ring of flame around the annular chamber.

c) Even pressure and temperature around the chamber.