Q. Basic principles of electromechanical energy conversion?

Energy available in many forms is often converted to and from electrical form because electric energy can be transmitted and controlled simply, reliably, and efficiently. Among the energy- conversion devices, electromechanical energy converters are the most important.

Electromechanical energy conversion involves the interchange of energy between an electric system and a mechanical system, while using magnetic field as a means of conversion.

Devices that convert control signals fromone formto another are known as transducers,most of which have an output signal in the formof electric energy. For example, a potentiometer is used to convert a mechanical position to an electric voltage, a tachometer generator converts a velocity into a voltage (dc or ac), and a pressure transducer indicates a pressure drop (or rise) in terms of a corresponding drop (or rise) in electric potential. Thus, a transducer translates the command signal appropriately into an electrical form usable by the system, and forms an important part of control systems. Electromechanical transducers form a link between electric and mechanical systems.

When the energy is converted from electrical to mechanical form, the device is displaying motor action. A generator action involves convertingmechanical energy into electric energy. The electromechanical energy-conversion process can be expressed as

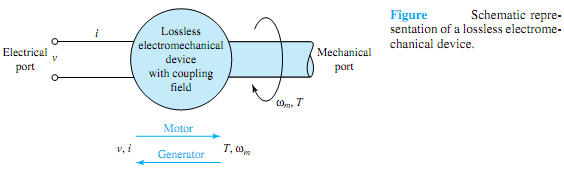

Electromechanical energy converters, simply known as electricmachines, embody three essential features: (1) an electric system, (2) a mechanical system, and (3) a coupling field. Figure is a schematic representation of an ideal electric machine (or a lossless electromechanical device) for which the following relations hold:

Electric input (or output) energy viΔ�t = mechanical output (or input) energy Tωm t or

Electric input (or output) power vi = mechanical output (or input) power Tωm

where v and i are the voltage and the current associated with the electrical port, and T and ωm are the torque and the angular rotational velocity associated with the mechanical port.