Reference no: EM131350856

Safety Assignment

Answer the following with a few grammatically-correct sentences for each section. Always spell-check before submitting your work.

1. Review the details of the Deepwater Horizon disaster on the Wikipedia article titled "Deepwater Horizon explosion" (https://en.wikipedia.org/wiki/Deepwater_Horizon_explosion).

a) Many warning signs and incidents occurred before the explosion, but engineers and management chose to ignore them. List three of these near-misses, and explain why each should have been viewed as a warning of the impending disaster (i.e. what specifically did they suggest might go badly wrong?)

b) Why were operational problems and concerns about safety not reported to (or acted on) by the upper management who were ultimately responsible for the Deepwater Horizon?

2. Read the article titled "Blowup" by Malcolm Gladwell (posted on Canvas).

a) Explain what is meant by the term "normal accident".

b) Why does our ever-growing reliance on complex safety systems in many aspects of our lives (e.g. antilock braking systems, network firewalls, smoke detectors, etc.) actually encourage people to take more risks than they would have otherwise?

3. Read the article titled "No One Knew He Was There" on the EHS Today website:

https://ehstoday.com/safety/confined-spaces/ehs_imp_35065

a) How was Garcia killed? What was the official cause of death? Who was ultimately responsible for Garcia's death?

b) List at least four general behaviors or actions that Garcia took, which violated accepted industry safe practices for work in confined spaces. (do not simply list four missing items of PPE, etc.)

c) Explain what was meant by "near-miss confined space fatality" in the article.

d) What is the main subject of the legal dispute between Garcia's family and Reynolds?

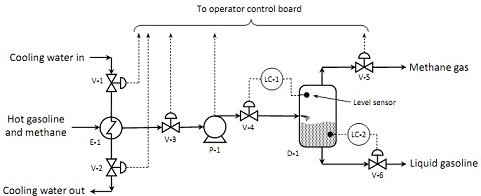

4. Consider the process flowsheet above. In this process, hot gasoline containing methane gas is pumped by a positive-displacement pump (P-1) into a separator drum (D-1). The methane gas and the liquid gasoline are separated in the drum, D-1. A heat exchanger (E-1) cools the hot liquid gasoline stream, to limit the loss of gasoline by evaporation in the drum. Valves V-4 and V-6 automatically maintain the liquid level in the drum, between set high and low limits. See the Crowl text for details of the symbols on the flowsheet diagram.

Signals (dashed lines) to and from the other valves and the pump allow remote manual control by an operator in the main control room. There are no people working near the equipment (good plant design). During a startup, the pump P-1 suddenly exploded in a large ball of fire. Although the pump and the connected piping are destroyed, the drum itself was only slightly damaged by the fire.

a. What is the most likely sequence of events that led to the destruction of the pump? List them in order of their occurrence. Hint: Use a "What-If?" analysis to consider what would happen if each of the labeled pieces of equipment did not operate as expected (either singly or together). What would cause that to happen?

Safe assumptions: Pipes carrying hot gasoline would be made from metal (conductive), so static electricity is not a concern. There is no oxygen/air in the gasoline/CH4 mixture, so it cannot burn/explode unless released to the atmosphere. The pump is rated for continuous operation at the maximum temperature of the hot gasoline feed. No open flames are present.

b. Draw appropriate reliefs on the diagram, wherever they are required to prevent catastrophic failure. Err on the side of safety in your final design, but please do not simply put a relief on every pipe or piece of equipment.

c. Describe a simple change that could be made to the piping or signal/control lines, which would completely and automatically eliminate the main cause of this explosion. Hint: Signals can be made to control equipment other than valves. Just adding a relief or two is not sufficient.

5. Assuming that the pump P-1 needs pressure relief, calculate the area and diameter of the required relief for the two major types of relief:

a) A conventional spring-loaded relief device

b) A rupture-disc device

Assume that the operating pump pressure is 120 psig, and that the relief system presents 10 psig of backpressure. The allowable overpressure is 15%.

6. The photographs below show a typical underground pump vault in a petroleum refinery. The pump is used to feed a liquid hydrocarbon stream (e.g. gasoline) to a nearby distillation tower.

a) Is the pump vault a permit-required confined space? Explain in terms of the formal definitions of confined spaces. What signage would be required for this area?

b) Using the Hazard Identification Tool which was distributed in class, identify at least three potential life-threatening hazards which might exist in the pump vault.

c) List the specific items of safety equipment that are required before anyone enters the vault to perform maintenance on the pump head.

d) List and describe the role of each person who is required to be involved in the maintenance operation.