Reference no: EM13336878

1. (a) In the event of a process being found to be incapable, what remedial action should be taken to bring it back within specification limits?

State the two types of causes of variations occurring in a process and provide a brief description of each.

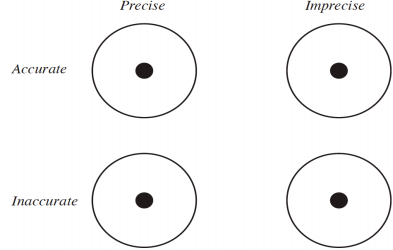

(b) Mark up the diagram opposite, using a pattern of dots in each case, to show the differences between "precise/imprecise" and "accurate/inaccurate" in SPC work.

2.

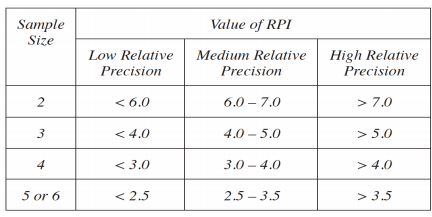

(a) Write an equation defining the Relative Precision Index.

(b) Two sets of components are being made. Inspection sample size is 4.

For set (1), the Total Specification Tolerance is 0.10 mm, and the average range is 0.05 mm.

For set (2), the Total Specification Tolerance is again 0.10 mm but the average range is 0.02 mm.

Calculate the Relative Precision Index in each case and, from the table on the following page, state the relative precision for each group.