Reference no: EM13858022

Problem 1

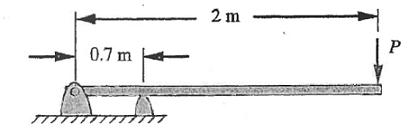

An overhung diving board is shown in the following figure with a cross-section of 305 mm x 3 mm. (a) Find the largest principal stress that will result when a 60-kg person jumps up 25 cm at the free end and lands back on the board. Assume that the board weighs 25 kg and deflects 10 cm statically when the person stands on it. (b) What is the static safety factor if the board material has an ultimate stress of 200 MPa in the longitudinal direction?

Problem 2

A journal and bearing are to be designed for a shaft that turns at 250 rpm. Suppose ISO VG100 (SAE Engine 30) is to be used as lubricant and the bearing length is to be equal to 1.2 times the diameter. If the no-load power loss is not to exceed 2.5 x 10-4 horsepower and the diametral clearance is 0.0045 times the diameter, estimate the maximum diameter that can be used for the journal, and the allowable temperature limit.

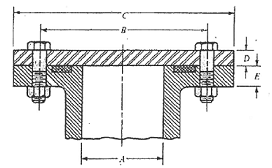

Problem 3

The figure below illustrates the connection of a steel cylinder head to a steel pressure vessel using 8 bolts and a confined-gasket seal. The effective sealing diameter is 150 mm. The other dimensions are: A = 100 mm, B= 200 mm, C = 300 mm, D = 20 mm and E = 25 mm. The preasnre vessel is used to store gas at a static pressure of 6 MPs. Metric 12 mm diameter bolts are to be used as they give a reasonable bolt spacing. The factor of safety for separation is to be at least 1.5 and the factor of safety for yielding is to be at least 2. Determine the required bolt preload and select a suitable grade of bolt.

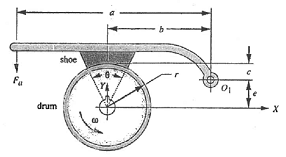

Problem 4

For a single short-shoe external drum brake with a drum width of 40 mm as shown in the following figure, find the torque capacity and required actuating force F. for a = 110 mm, b = 70 mm, e= 25 mm, r = 35 ram, and e = 40°. Wien value of c will make it self-locking? Assume the maximum allowable lining pressure is 1.3 MPa and the friction coefficient for the brake lining material is e = 0.3.

Problem 5

Briefly answer the following questions:

(a) What is 00,2 ?

(b) For an isotropic material, in biaxial stretching, which one will predict lower stresses at the onset of yielding, the Mises criterion, or the Tresca criterion?

(c) Why is a hollow shaft preferred over a solid shaft?

(d) For a plain (journal) bearing with the following data: 45-mm diameter, 200 mm long, eccentricity ratio c = 0.55, clearance ratio = 0.001, 2500 rpm, and ISO VG220 (SAE Engine 50) oil of 150°F, find the minimum film thickness.

Problem 6

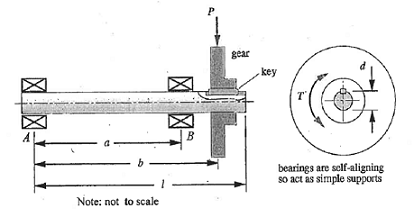

A shaft is simply supported at A and Bas shown. A constant magnitude transverse load P is applied on the gear (with no weight to be considered) as the shaft rotates subjected to a time-varying torque from the minimum of- 200 lbin to the maximum of 500 lb-in. If I= 17 in, a = 6 in, b = 12 in, and P =1500 lb, perform the following:

(a) Find the shaft diameter required to obtain a safety factor of 2 in fatigue loading if the shaft is steel with ultimate strength of 108 ksi, and yield strength of 62 ksi. Assume no stress concentration (ignore the key in your calculation). What would be the maximum deflection in beading of the shaft?

(b) Determine the size of parallel key necessary to give a safety factor of at least 2 against both shear and bearing failure for the design shown using the shaft diameter found in (a).

(c) Choose a suitable 6300 ball bearing from attached Fig. 10.23 for a 5% failure rate. Select the bearing that has the least bore diameter and meets the load-rating requirement. Specify bearing number, bore, OD, width (all in in.) and the basic dynamic load rating of the bearing. Using LID = 60 (millions).

Problem 7

Briefly answer the following questions:

(a) Name at least five green design criteria.

(b) Why is a hollow shaft preferred over a solid shaft? What are the disadvantages of a hollow shaft?

(e) Describe the relationship between the Ocvirk number and the applied load, and what is the suggested Ocvirk number in bearing design?

(d) What happens when the eccentricity ratio equals one in a journal bearing?

Problem 8

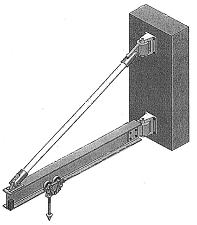

A well mounted jib crane is shown in figure 1. The boom is to be made of a standard structural steel I beam and is to have a span of approximately 3050 ram. The hinge distance from the wall to the edge of the beam is approximately 100 mm. The crane is to have a capacity of 18 kN and a factor of safety of 3 on yielding. When the trolley is extended fully carrying the maximum load the end deflection of the boom should be less than 6 mm. Clearly state your objectives, constraints, and metrics for the objectives and justify your decisions when answering the following,

a) Select a suitable standard I beam for the boom (tables are attached).

b) Select a suitable material and diameter for the tie rod which supports the boom assuming a suitable angle between the boom and the tie rod.

c) Specify a suitable weldment size and pattern for the plate which holds the tie rod cleats bracket to the free end of the boom.

d) The trolley is supported by four rollers, two on each side which ride on the flange of the boom. Specify suitable standard ball bearings which could be used for these rollers.

Problem 9

A full journal bearing has a shaft journal diameter of 2.000 inches and a unilateral tolerance of -0.0012 inches. The bushing has a bore diameter of 2.0024 inches and a unilateral tolerance of 0.002 inches. The bushing is 1 inch long and supports a load of 650 lb, at a speed of 825 rev/min. Determine, for an average film temperature of 130 °F and SAE 20 lubricant ;

a) The minimum film thickness

b) The power loss

c) The total lubricant flow.

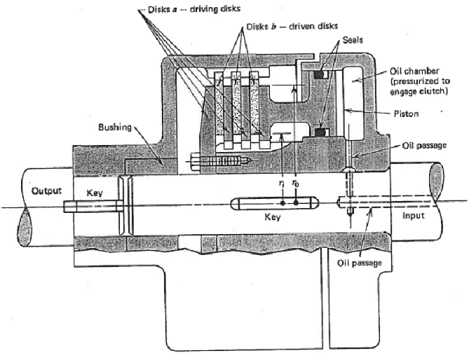

Problem 10

A multiple-disk wet clutch, similar to the design shown in figure 3, is to be designed to transmit a torque of 85 N-m. Assembly space restrictions limit the outside diameter 2r; to 100 mm. Design for the friction material and steel disks to be used are dynamic friction coefficient, f x.06 (wet) and maximum disk allowable pressure, =14001cPa. Determine appropriate diameters for the disk inside diameter 2ri the total number of disks and the required clamping force.

Problem 11

The tensile offset yield strength of ALSI 1045 cold-drawn steel bars of one inch diameter is reported histographically as shown in the table below.

|

Sy (kpsi)

|

93

|

95

|

97

|

99

|

101

|

103

|

105

|

107

|

109

|

111

|

|

f

|

22

|

26

|

37

|

18

|

11

|

9

|

4

|

3

|

4

|

1

|

Where Sy is the class midpoint in kpsi and f is the number in each class.

a) Assuming that the distribution is normal, what is the yield strength exceeded by 99 percent of the population.

b) Determine if the distribution of the data is normal.

Problem 12

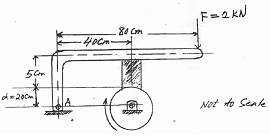

A single block brake commonly used on the railway trains and tram cars is shown in the Figure below. After applying the 2kN actuating force, the clockwise rotating drum comes to a complete stop in 5 seconds. During this time the drum makes 120 revolutions. The coefficient of friction between the drum and lining is 0.4. Perform the following;

a) Sketch the brake shoe and arm assembly as a free body diagram.

b) Determine the torque that may be transmitted by the block brake.

c) Calculate the horizontal and vertical reaction forces atpoint A,

d) Is the brake self-locking for the direction of drum rotation as shown?

e) Determine the energy dissipated to bring the drum to a complete stop.

f) To make the brake self-energizing for the clockwise rotation, what should be the size of d?

Problem 13

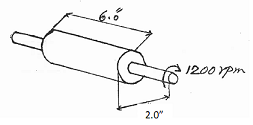

A sleeve bearing has a diameter of 3.75-in and it is 6-in long. The shaft speed is 1200 rpm and oil temperature is 180 OR The friction loss in the bearing is 0.2 hp. The diametric clearance between the journal and bearing is 0.005-in. The eccentricity can be considered as 0.6. Determine the following;

a) The total load on the bearing.

b) The average pressure in the oil film.

c) The stationary and rotating torques.

d) The minimum oil film thickness.

Problem 14

A single square thread power screw has 3kW input power with a rotating speed of 1 rev/sec. The screw has an outside diameter of 36 mm with one continuous thread having a pitch 6 mm. The frictional coefficients are 0.14 for the thread and 0.09 for the collar, with an effective collar friction radius of 45 mm. Determine the following;

a) Show that screw has a pitch diameter of 33 mm.

b) The size of the load being moved by the screw.

c) The screw efficiency.

Problem 15

A 15,000 lb elevator is supported by a steel wire rope having 2.0-in, cross-section and an effective modulus of elasticity of 12x106 psi. Due to an unexpected accident the steel wire rope SO ft above the elevator suddenly stopped. At the time of accident the elevator was running at a constant speed of 300 ft/min. Determine the following;

a) Impact factor due to sudden stop.

b) The maximum elongation of the rope.

c) Maximum tensile stress developed in the wire rope.

Problem 16

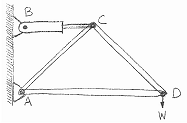

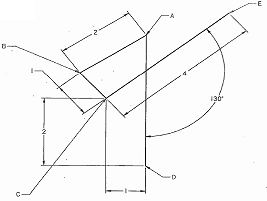

The above sketch represents a simple device used to lift a weight at point D. The hydraulic cylinder between points B and Cis used to lift the weight over a small displacement. Assume:

• Link AD is horizontal in the above sketch and has a length of 1000 mm.

• Links AB and BC are 500 mm each.

• The weight (W) Is 20 kN.

• The links are In-plane and made from AISI 1006 cold-drawn steel, The links have a square cross-section.

The factor of safety used in the design Is 1.5.

Answer the following questions:

a, What are the reaction forces at points A and B?

b. If the hydraulic cylinder retracts 10 mm, what will the vertical displacement be at point 0?

Problem 17

The tensile offset yield strength of AISI 1137 cold-drawn steel is reported histographically as follows. Assume a lognormal distribution.

Sx (kpsi) 93 95 97 99 101 103 105 107 109 111

f 22 26 37 18 11 9 4 3 4 1

For a safety factor of 1.5, estimate the percentage of components made of this material that plastically deform at a stress of 100 kpsi.

Problem 18

An Acme thread power screw has a major diameter of 38 mm and a pitch of G mm with double threads. Assume f = 0.14, fr = 0.08 and cf, = 45 mm„

a. At what force is the screw self-locking?

b. What is the combined efficiency of the screw and collar at this force?

Problem 19

A 2 inch diameter bearing has a length of 3 inch and has a central annular oil groove 0.25 inch wide that is fed by SAE-10 oil at 120• and 30 psi supply pressure. The average radial clearance is 0.0015 Inch. The journal is rotating at 3500 rev/min and the average pressure is 600 psi over the projected area. Find the temperature rise, the minimum film thickness, and the maximum film pressure.

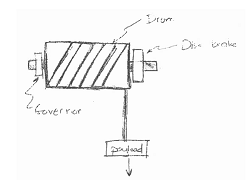

Problem 20

Design a disk brake for a half-tonne hoist that lifts and lowers a payload attached to a cable, The cable Is wrapped around the 0.5 m diameter drum. A constant speed centrifugal governor limits the lowering speed to 1 m/s. The drum weighs 100 kg and has a radius of gyration of 0.2 m. The multiple disk brake is mounted as shown below. The brake must bring the payload to a stop in 0.5 s and the axial actuating force on the brake must not exceed 10 kN. Design the disk brake system Including number of disks, their diameter and thickness, the required actuating force, and temperature rise in the system.

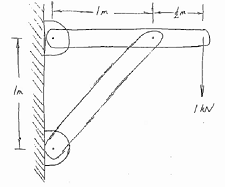

Problem 21

For the two bar linkage shown above, select a material, method of manufacture, and cross-section, The design objectives are safety and economy. State your objectives, constraints, and metrics for the objectives. For buckling In the plane of the linkage, assume the link is pinned at both ends. Assume the ends are fixed for out-of-lane buckling. Justify your decisions,

Problem 22

A power screw used to resist a vertical load uses a 5/8 inch-6 Acme thread, The frictional coefficients are 0.05 for the threads and the collar. The collar has a friction diameter of MG inch.

a) Find the minimum vertical load at which the load will lower Itself without any external effort.

b) Determine the torque required to raise this load.

c) Find the von Mises stress and maximum shear stress at the root.

Problem 23

The following are histographic results from tensile testing of a batch of steel components.

|

Tensile Strength (MPa)

|

164

|

165

|

166

|

167

|

168

|

169

|

170

|

171

|

172

|

173

|

174

|

175

|

176

|

177

|

178

|

|

Frequency

|

3

|

7

|

11

|

16

|

21

|

1.3

|

1.3

|

6

|

2

|

0

|

4

|

3

|

0

|

0

|

1

|

|

Elongation In 2 In, %

|

29.4

|

29.5

|

29.6

|

29.7

|

29.8

|

29.9

|

30

|

30.1

|

30.2

|

30.3

|

30.4

|

30.5

|

30.6

|

|

Frequency

|

1

|

4

|

3

|

2

|

12

|

24

|

18

|

12

|

11

|

3

|

4

|

5

|

1

|

Assuming lognormal distributions, estimate the modulus of elasticity for which 95% of the corn ponents will be stiffer.

Problem 24

The above diagram is schematic of a small manual press or juicer. Points C and D are grounded, Link AD has variable length, Link Al is heed length. Link BCE is rigid with a right angle between lines BC and CE. The dimensions are in inches. The user exerts a force up at E causing A to be become displaced down for the given position of 130 degrees. For this position, determine the following.

i. The ratio of vertical force provided by the user at Eta the output force and A.

ii. The ratio of displacement in the vertical direction at E to the vertical displacement at A.

Problem 25

The above figure is a schematic representation of a slider-crank mechanism. Points A, B, and Care pinned joints. Links AB and BC are 10 cm and 30 cm long, respectively.

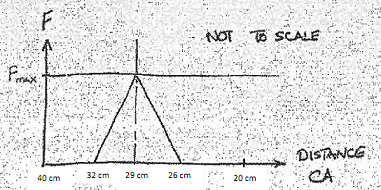

a) Write an expression for the torque at point A given in terms of the Input force F. Document any assumptions.

b) Given the below function diagram for the force F in terms of the location of the piston at C compute: the maximum torque in terms of F and compute the position of the piston at maximum torque.