Reference no: EM131467879

Question: Team Project Problem. The MicroTex Corporation makes special purpose microprocessors that are used in a variety of machines. The company produces two products as variants from the same processing procedure. The products are distinguished after one layer or single sequence through the processing steps. After the first layer has been completed, the wafers go through a test operation; wafers are characterized as worthless (waste), bad and in need of rework, good wafers but low cycle speeds, and excellent with high cycle speeds. Product 1 is made from the low cycle speed processors that are immediately packaged and shipped. The high-speed units are processed further by a second sequence through the basic operational steps (using the same machines as previously) and then a final test is performed. Units again are characterized as waste, rework and completed units (no low speed units can come out of the second test). The completed units are then packaged and shipped as the company's high-grade product. Microprocessor chips are produced by a process that starts with pure silicon wafers that are fragile, flat, thin circular objects that look similar to glass.

Patterns are placed on the wafers by covering them with a photo-resist material and then exposing the images onto the resist by shining light through a template or mast of the desired image. The images are hardened by baking the wafer in an oven. A pattern of holes is then etched into the mask layer by removing the exposed material. This allows the dopants to be diffused into selected areas of the wafer. Specific ion atoms (dopants) are implanted on the exposed surface (boron, phosphorous, and arsenic) by diffusion processes. These processes are repeated hundreds of times to produce a state of the art microprocessor. Then a wafer probe is used to functionally test the individual processors on the wafer and characterize their performance potential. The completed wafers are diced into single chips with a diamond saw and then attached via glue to a package. The package provides the contact leads to the chip. Wire bonding, generally with gold leads, is used to connect the package leads to the wire connections within the chip. Then the package containing the chip is encapsulated with a plastic coating for mechanical and environmental protection.

The MicroTex wafer fab is a state-of-the-art pilot facility with the latest cluster tool technology. These fabrication processes are performed in three basic steps. The first set of processing steps is performed in Workstation 1 with a pair of identical single wafer processing equipment (machines). At the second workstation, the remaining set of operations is performed in a batch mode using a single large capacity (up to eight lots simultaneously) processor (similar to an oven operation). A third workstation contains a single testing machine used to determine the wafer performance characteristics. Workstation 4 consists of the packaging operations also performed using a single piece of equipment. All of the completed products received the same general processing using the same equipment, although the processing times vary for the second production pass. The wafer units that have graded out as high quality and speed are processed further. To prepare for the second layer, the second time through the processing steps, a separate distinct set of processing must be performed. This preparation processing step is distinct from previous processing and, therefore, these operations are performed on a separate machine in Workstation 5. When completed, these units are sent back through the first three workstations for another sequence of processes. The second sequence of processing has distinct times from those of the first sequence, except for the batch operations of Workstation 2. This is fortunate, allowing batching at Workstation 2 to be indiscriminate of the type of wafers being processed. That is, batches can consist of either or both types of wafers. If the high quality product wafers grade out acceptably they are also then packaged at Workstation 4 and shipped.

Phase I: MicroTex management would like your consulting team to develop a model of their facility and help them answer questions concerning potential areas of improvement. The first phase of the project is to utilize their best guess data, compiled by their lead engineers, and develop a preliminary model of their company. If they find this result acceptable, they will allow your team access to the actual company proprietary data from which accurate and meaningful data can be developed. This refined model will then be used to develop strategies for future company improvement and new product development. These types of facility are extremely expensive to build, frequently costing from one to two billion dollars for a full scale facility. Thus, continuous operation of the facilities is maintained at all times; 24 hours a day, seven days a week. The work release rate for the pilot facility is one job (lot of 24 wafers) per hour. All times are given in lot units. The mean times for the first three processing steps are estimated to be 1.15, 2 and 0.25 hours, respectively. The test operation on average finds that 10% of the processed wafers are scrapped and 15% can be reworked and are thus reprocessed at Workstation 2. Of the acceptable units, only 1/3 grade out as high quality and speed and go through further processing. The packaging operation for the low or first level product takes 45 minutes while the high quality product takes 54 minutes. For the high quality product, the unique first additional step takes 2 hours and 15 minutes. The company policy is that when (on the first trip through only) a lot is scrapped, it is replaced with a new lot start. The second trip through workstation one takes 75 minutes and in Workstation 3 the second trip requires an additional 3 minutes over the first processing time. The batch size used in Workstation 2 is a fixed quantity of four jobs (four lots of wafers). This is a carryover from a previous production line where the machine capacity was limited to four lots. For the pilot factory, the number of machines in Workstation 1 is two, the number of ovens in Workstation 2 is one, and the number of machines in Workstation 3 is one. For this pilot system analysis, we can assume that the order release process (external arrival process) and all service processes have squared coefficients of variation with values of 1. MicroTex wants a short written report of your consulting team's preliminary model to determine if your consulting team will be continued into the actual factory analysis phase.

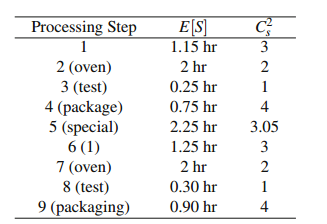

Phase II: The MicroTex Corporation accepts your design team as the company's consulting team for the wafer fabrication pilot facility study. During your preliminary analysis period, the company has had a team of industrial engineering coop students collecting time study data for all the machines used in the facility. The coop group finished the analysis on four of the five machine types and furnished the following table:

The current pilot facility has a cycle time around 65-70 hours. Management has a quality improvement program in place and they predict that scrap losses can be reduced to 5%, rework can be reduced to 10%. In addition, engineering believes that the processing times variations can be reduced across the board by 50%. Can the management goal of a cycle time of less than 35 hours be reached? Engineering is always working to improve the high speed wafer yield percentage. These units are worth considerably more and have an unlimited market. Engineering feels that this yield percentage can be drastically improved, but maintaining the cycle time goal of 35 hours will be impossible. Management has, therefore, agreed to allow one more machine (of any type) to be placed in the pilot facility if necessary. What is the maximum high speed wafer yield percentage that can be accommodated within the 35 hour cycle time guideline? The real goal of the pilot facility is to determine what facility configuration is necessary for a full scale facility with a release rate of 10 lots per hour. We can assume that all of the learning with respect to yields, variation reductions, etc., carry over to the new facility. Assuming that the best yield results for the pilot facility can be maintained in the new plant, what is the machine configuration and estimated cycle time for this facility?