Reference no: EM133143490

Assessment task 1

Question 1

a) What are the advantages of low and non-waste technology (LNWT) (or clean technology) over end-of-pipe treatment?

b) List the main human barriers to waste minimization efforts in industries.

c) Write in your own words, what good house - keeping in an industry means?

Question 2

The waste contributing steps to tomato processing industry is listed below with quantities and biochemical oxygen demand (BOD5) and suspended solids (SS) values

|

Stream

|

Process Unit

|

Flow (L/min)

|

BOD5 (mg/L)

|

SS (mg/L)

|

|

#1

|

Prewashing units

|

1890

|

75

|

180

|

|

#2

|

Washer

|

1000

|

90

|

340

|

|

#3

|

Boiler feed water

|

1136

|

30

|

20

|

|

#4

|

Cooker

|

45

|

3520

|

7575

|

|

#5

|

Processing unit #1

|

70

|

4410

|

8890

|

|

#6

|

Processing unit #2

|

570

|

230

|

170

|

|

#7

|

Processing unit #3

|

380

|

450

|

540

|

a) Provide a suitable waste segregation (separation) and treatment scheme

b) What will be the flow and BOD5 concentration of the combined stream of #4 and #5

Question 3

Food waste characteristics are given below:

- BOD5: 400 mg/L

- COD: 650 mg/L

- Suspended solids: 250 mg/L

- pH: 4

a. Compare the quality of this wastewater with that of domestic wastewater (the indicative values are sufficient).

b. Suggest a treatment system with a short explanation.

Question 4

Suggest a treatment method for reuse or by-product recovery for the following wastes.

a. Dairy (milk) waste containing whey (protein) material

b. Cutting oil waste coming from metal cutting machines

c. Dye waste from cloth dyeing (textile) industry.

Question 5

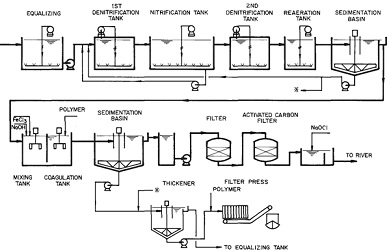

Using the flow diagram given below explain the role of

a. Filter

b. Activated carbon

c. Filter press

d. Equalization (equalizing) tank.

Question 6

Calculate the annual cost for the use of rechargeable Nickel-Cadmium AA and compare it to the annual cost for conventional batteries. They are to be used in a portable radio which uses six such batteries. What is the payback time, if any? Other details are as given below:

|

|

Conventional AA

|

Rechargeable Ni-Cd AA

|

|

Number required

|

6

|

6

|

|

Cost (each)

|

$ 0.80

|

$4.20

|

|

Rotation frequency

|

Monthly

|

Monthly

|

|

Solar re-charger cost

|

0

|

$ 18

|

|

Life time

|

1 month

|

5 years (1000 charges)

|

Question 7

A cannery receives on a given day 12 tons of raw produce, 5 tons of cans, 0.5 tons of cartons, and 0.3 tons of miscellaneous materials. Of the 12 tons of raw produce, 10 tons become processed product, 1.2 tons end up as produce waste, which is fed to cattle, and the remainder is discharged with the wastewater from the plant. Four tons of the cans are stored internally for future use, and the remainder is used to package the product. About 3 percent of the cans used are damaged. Stored separately, the damaged cans are recycled. The cartons are used for packaging the canned product, except for 5 percent that are damaged and subsequently separated for recycling. Of the miscellaneous materials, 25 percent is stored internally for future use; 50 percent becomes waste paper, of which 35 percent is separated for recycling with the remainder being discharged as mixed waste; and 25 percent becomes a mixture of solid waste materials. Assume the materials separated for recycling and disposal are collected daily.

Prepare a materials balance for the cannery on this day and a materials flow diagram accounting for all of the materials.

Also determine the amount of waste per ton of product.

Question 8

Based on the data provided below, calculate the charges for disposal of the waste with and without recycling at the transfer station, and comment on these costs

Waste generated 10 tonnes

Recyclable waste 70 %

Transport costs $ 1 per tonne per km

Distance to landfill 120 km

Location of transfer station mid way

Cost of recovery at transfer station $10 per tonne

Sale value of recyclable goods $15 per tonne

Tipping cost $50 per tonne

Assessment task 2: Waste Minimisation Methodologies and Practices

• Intent: In this assessment task, students carry out processes in industrial waste minimisation that are representative of current practices of waste reduction and cleaner technology used by industry.

• Objective(s): This assessment task addresses the following subject learning objectives (SLOs): 2 and 4. This assessment task contributes to the development of the following Course Intended Learning Outcomes (CIL0s): B.1, and D.1.

• Task: A professional report will need to be submitted for this assessment task.

Students will be required to explain the processes in industrial waste minimization, demonstrate design procedures and provide practical recommendations on industrial waste minimisation.