Reference no: EM133004427

SEHS4673 Heat and Mass Transfer - The Hong Kong Polytechnic University

Assignment 1

Q1. A long mild steel pipe (k = 15 W/mK) having an outer diameter of 22 cm and an inner diameter of 20 cm is used to deliver saturated steam at 120 °C for central heating purpose. The pipe is exposed to the outdoor environment at 10 °C. Heat transfer coefficient at the outer surface of the pipe is 8 W/m2K whereas that at the inner surface of the pipe is 30 W/m2K. A thermal insulation (k = 0.04 W/mK) is applied on its outer surface to reduce heat loss from the steam. By neglecting radiation, determine the thickness of thermal insulation required if the heat loss from a unit length of pipe to the outdoor environment is limited to 30 W.

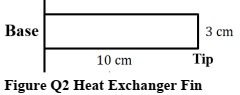

Q2. A fin array of 10 rectangular heat exchanger fins (uniform cross-sectional area), each 2 mm thickness, is used to cool a power transistor. The base temperature of fin is 120?. The tips fins are insulated. Fin thermal conductivity is 180 W/m·K. Air flows over the fins with a convection coefficient of 12 W/m2·K and air temperature is 25?. The length and width of the fins is 10cm and 3cm, respectively. Find

(a) the heat transfer rate of the fin array,

(b) temperature at fin tip.

Q3. A double-glazed window (k = 0.76 W/mK), 1.4 m high (L) and 2.3 m wide, consists of two layers of glass each 3 mm thick separated by an air gap 20 mm thick (S). The window is installed in the wall of a room in which the room air temperature is maintained at 23 °C. Outer surface of the window is exposed to the atmospheric air at a temperature of 2 °C. Heat transfer coefficients at the room-side surface and the exposed outer surface are 5.7 W/m2K and 9.1 W/m2K, respectively. Determine by neglecting radiation the heat loss through the window by assuming:

(a) Air in the air gap is stationary with a thermal conductivity of 0.026 W/mK.

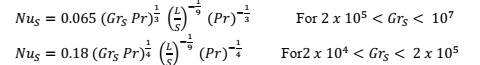

(b) With the aid of Table Q3, the heat transfer coefficient of the entire air gap is determined from:

Q4. A "1-shell-pass and n-tube-pass" recuperative heat exchanger is used to condense 0.4 kg/s of steam at 0.7011 bar to saturated water at the same pressure (latent heat = 2550 kJ/kg). The steam condenses on the external surface of the tubes, and each tube has an internal diameter and an external diameter of 36 mm and 42 mm. Cooling water enters the tubes at 8 kg/s and 20 °C. The velocity in the tube is maintained at 0.198 m/s. Heat transfer coefficient on the steam side is 2 kW/m2K, whereas that on the water side can be obtained from with the aid of Table Q4: Nud= 0.023 Red0.8 Pr0.4

Calculate under steady-state conditions and negligible radiation, the number of tubes and the length of each tube required. Thermal conductivity of the tube wall is 50 kW/mK.

Q5. Due to formation of scale of high thermal insulating property (k = 0.056 kW/mK) on the internal tube surface, performance of the recuperator as described in Q19 deteriorates with time. Assuming a scale formation rate of 0.2 mm per month, show that the water outlet temperature will be reduced to 48°C (which also implies a reduction of heat transfer rate between the two working fluids of 8%) after the recuperator has been operated for a period of 10 months without proper cleaning. The following assumptions can be made:

(i) The mass flow rates of water and steam maintain unchanged;

(ii) The water-side and steam-side heat transfer coefficients are unaltered; and

(iii) The scale is formed with uniform thickness along the tube length.

Attachment:- Heat and Mass Transfer.rar