Reference no: EM13862140

Part 1

Question 1)

Carbon Revolution is looking for someone that can supply 250,000 aluminium alloy backing plates a year to go into their carbon fibre composite wheels and do not mind whether they are manufactured by die casting or machining. Your company does not have the equipment to do either, but are willing to quote since it would be long term contract. They have asked you to generate a preliminary cost comparison to see which process would be cheaper and hence which process you would recommend developing a quote around (at which stage a more detailed cost analysis will be conducted by someone else in your company).

In generating your cost comparison you should use the Ashby cost equation from the first week's lectures. You only need to focus on the machining and die casting processes and in particular the differences between the processes as they affect the cost equation (i.e. don't worry about factors outside the process such as indirect labour or electricity use, or the hard anodising process that would be conducted after the plate is made). You are free to make whatever assumptions you need to, however, it is important that you clearly state them. Include any references you use to justify the numbers you have chosen to use in your cost model.

Marking criteria - the most important aspect is that you use the cost model correctly and use thoughtful inputs to the cost equation that highlight the comparison between the two processes. You do not need to spend a lot of time attempting to find exact numbers for any of the variables that go into the cost equation.

Question 2)

Carbon Revolution have made it clear that quality is an extremely important aspect to their business and they expect high quality from their suppliers. Identify 3 keys things that you would recommend to your company that they need to measure as part of the process or quality control for whichever process you selected in question 1. Clearly state for each of the 3 what you think should be measured and why.

Part 2

Question 1)

Watch the week 2 demonstration video on making a sand mold. By estimating the dimensions of the sprue, gating- system and screwdriver handle, calculate the following:

• Flow velocity into the screwdriver handle mold cavity

• Volume rate of flow into the screwdriver handle mold cavity

• Whether the flow is turbulent or laminar

• Solidification time (assuming that the constants from Chvorinov's rule are n=2 and C=2.5 s/mm2)

Question 2)

Identify three things that could be significantly improved in the sand mold design if our intent was to produce screwdriver handles commercially. Explain what would be improved for each thing you identify.

Part 3

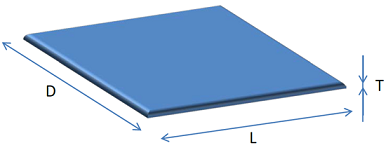

Question 1) Injection moulding

During the injection moulding of a flat part (similar to the one below), what happens if:

- The injection time is too short?

- The injection time is too long?

- The injection pressure is too low?

Use drawing if it helps explaining.

Question 2) Extrusion

You are running an extrusion run loading Nylon 6 with short glass fibres in order to improve its mechanical properties and creep properties.

You are aiming for a 30% in weight of glass fibre loading in your Nylon 6 to obtain the required properties.

You are running at a certain screw speed (i.e. shear rate), your temperature profile along the extruder is set to 260 °C (40 °C above the melting point of Nylon 6); your Nylon 6 fed rate is set to X kg per hour and your glass fibres are also fed at a rate of 0.3X kg per hour.

Your extruder is not running properly, it is clogging at the die head.

What is happening? Suggest two parameters which should be changed in order to improve your run? Explain your reasoning.

Part 4

Composite manufacturing

Question 1) Explain the importance of de-bulking your composite during lay-up. If this process if not done properly, what consequences does it have on the properties of the resulting cured composite?

Question 2) The composite industry (in particular the aerospace industry) is always trying to achieve a maximum fibre volume fraction in their composite. Why? Conversely why is it important to minimise the resin content in a composite?