Reference no: EM132900791

PCI360S Process Control and Instrumentation

Assignment 2

This assessment will test the following Graduate Attribute as stipulated by ECSA Graduate Attribute 2 - Application of scientific and engineering knowledge

Question 1 Process response to step change forcing function: Materials and Energy Balances

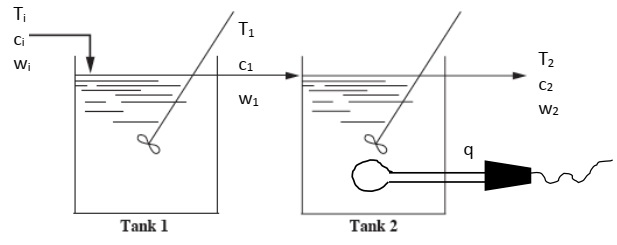

The production of certain industrial chemical of high economic value involves a two-tank mixing unit operation in which one of the tanks is heated as shown below. The volumetric flow rate is designated by w (m3/h); the temperature of the inlet stream, T, and the concentration of the salt water is c. The volume of each tank is 5 m3, mass flow rate is 250 kg/h and density is 50 kg/ m3

A: Material balance

(i) Using an appropriate mass balance equation, derive the differential equations that can be used to describe the change of the salt concentration of tanks as a function of their inlet concentrations.

(ii) Derive the transfer function relating the change in the salt concentration in tank 2, C2, to the change in inlet concentration in tank 1, Ci.

(iii) Set up an Xcos model to find the tank responses to the system inputs highlighted in Items

(iv) below. Note that you should show a plot of the input to the first tank as well as plots of the responses from the first and second tank on the same graph. For this question, you can change the value in the 'Period' tab of the 'Red clock' block from the default value of '0.1' to '1'. This is to enable you have a faster graphical plot.

(iv) Show graphically using Scilab/Xcos the responses of both tanks for a step change in the salt concentration in tank 1 from 1 kg salt/m3 to 3 kg salt/m3

(v) Based on the responses obtained in (a) above, determine the concentration out of Tank 1 and the concentration out of Tank 2 at the following conditions:

(a) t = 120s after the step change 2.5

(b) t = infinity 2.5

B: Energy balance

(i) Using an appropriate energy balance equation, derive the differential equations that can be used to describe the temperature change in the tanks as a function of their inlet 5 temperatures.

(ii) Derive the transfer function relating the change in the temperature of tank 2, T2, to the change in inlet temperature in tank 1, Ti and the change in the heat input to tank2, Q [this 10 expression should contain numerical values of the parameters]. When the inlet temperature is T1=60oC, the outlet temperature in tanks 2, T2 =75oC, calculate the steady state heat input, Q into the system.

(iii) Set up an appropriate Xcos model to find the tank responses to the system inputs highlighted in Items (iv) below. Note that you should show a plot of the input to the first tank as well as plots of the responses from the first and second tank on the same graph.

For this question, you can change the value in the 'Period' tab of the 'Red clock' block from the default value of '0.1' to '1'. This is to enable you have a faster graphical plot.

(iv) Show graphically using Scilab/Xcos the responses of outlet temperatures, T1 & T2 in the tanks If a step change in heat input is 100J/min, and the temperature of the inlet liquid drops from 60oC to 52oC according to a step function.

(v) Determine the final temperature of tank 2 due to the step inputs in (iv) above.

Hint: Heat capacity of liquid (salt water) is 1J/kg oC

Attachment:- Process Control and Instrumentation.rar