Reference no: EM13870153

Question 1:

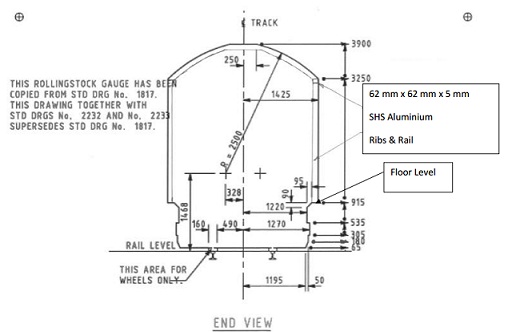

Figure 1 (a) & (b) show some preliminary drawings of a passenger railway carriage that was supplied to a design engineer to confirm the thickness of Aluminium sheets needed to fabricate the superstructure of the carriage. The superstructure's side and top walls will be manufactured entirely from thin Aluminium sheets of a single thickness. There are three thicknesses of Aluminium sheets available to choose for fabrication, 2.5 mm, 3 mm and 4 mm. The following are some of the important details provided to the design engineer by the wagon designer.

1. Weight of attachment on the canopy surface (curved structure)of the superstructure can be considered as a 35 kg/m2 weight load

2. Weight of attachments on the side surface (walls above the floor)of the superstructure can be considered as a 30 kg/m2 weight load

3. Corner radii of cut-outs are 50 mm.

4. The super structure will be rigidly attached to the floor.

5. The stress acting on the super structure needs to be kept at minimum levels as much as possible at 2.5g acceleration of a wagon. Usually keep stress level under 50 MPa as much as possible.

Your task:

- Create a suitable FEA model using Creo Parametric + Simulate.

- You can assume missing dimensions if it is essential for your analysis. You need to explain why you believe these assumptions are necessary.

- You need to minimize the size of your model as much as possible, using symmetry and substructuring for the analysis. You need to perform appropriate analysis to investigate identified locations of stress concentrations such as corners of cut-outs (i.e. doors & windows)

- Determine a suitable thickness of Aluminium sheet to satisfy the design criteria. (You need to consider excessive stresses, weight issues for your decision)

- Provide a FEA report including appropriate stress strain plots and deformed shapes etc. (All dimensions in Figures 1 (a) and (b) show nominal values in millimetres unless otherwise stated. Do not scale the drawings)

Note: You need to create material properties for Aluminium in Creo 2.0 simulate

Figure 1(a)

Question 2:

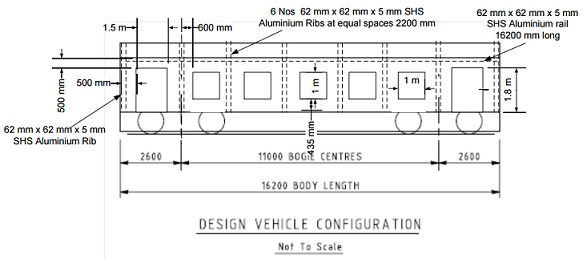

Figure 2: A stainless steel pressure vessel.

A sectional view of a stainless steel pressure vessel is shown in Figure 2. The pressure vessel needs to be installed in a rigid concrete cover as shown. Assume there is no clearance between the vessel and the concrete enclosure walls. The initial conditions of the vessel estimated as ambient pressure, 1 bar and ambient temperature, 25 0 C. Major design dimensions are shown and the thickness T needs to be determined by a FE Analysis. The vessel needs to withstand 4 MPa internal pressure and temperature increased up to 800 C. The vessel needs to be designed for 25% pressure surges and maximum stress in the vessel walls of less than 150 MPa. You need to check your answers with appropriate manual calculations. (Assume the concrete cover adjacent to vessel's outer reaches 80 0 C at the steady state. The dome section of the vessel is open to ambient air and heat flows by convection (Coefficient of convection for air 80 W/m2

/K) Perform trial manual stress calculations (without thermal stresses) for the dome and the vertical walls of the pressure vessel.

Determine a suitable trial value for thickness "T ". Use the trial value for FEA and refine it until you meet the optimal design criteria.

1. Justify your design by axi-symmetric FEA (2D FEA- Combined static & thermal).

2. Provide stress/strain/deflection plots as necessary.

3. Perform a appropriate 3D analysis (Combined static & thermal) of the pressure vessel and compare your 2D FEA results with 3D FEA results.

Note: You need to create material properties for Stainless Steel in Creo 2.0 simulate

Question 3:

Perform a design analysis for a combination spanner (chose a size from the range 12mm - 24 mm). A representative example is shown in Figure 3.

(You will need to find appropriate dimensions for your chosen spanner)

Your task:

1. Determine design parameters relevant to the spanner such as materials, nominal operational force/moment/torque, details of design practices, standards (if there is any) and safety measures.

2. Perform your analysis on both ends of the spanner.

3. Create your own geometrical design for the selected spanner size.

4. Perform necessary hand calculations to support your design

5. Create a suitable solid model for the spanner in Creo2.0 and perform a FEA analysis

6. Provide a report which includes your design, design parameters and hand calculations. The report must show the details of your FEA including appropriate stress/strain plots and a comparison of hand calculations with FEA results.

Note: You need to create material properties for tool steel in Creo 2.0 simulate (Results should be tabulated appropriately and sketches should be used wherever necessary)

|

Find the horizontal asymptotes of the curve

: Find the horizontal asymptotes of the curve y — V9x6 — x x3 + 1 Find the horizontal and vertical asymptotes of the graph of f (x) — e2s + 4e2c — 5.

|

|

Define header files

: Define Header files. Define main()function Declare local variables and assigning values to variables.

|

|

Identifying main ideas and supporting detail

: Helpful Resources: Identifying Main Ideas, Supporting Evidence/Details, and Summarization. Identifying Main Ideas and Supporting Detail

|

|

Prepare the journal entry that jna will make to record

: Prepare the journal entry that JNA will make to record the promissory note created on April 30, 2015. Prepare the journal entries that JNA will make to record the interest accruals at each quarter end and interest payments at each payment date. Prepa..

|

|

Preliminary drawings of a passenger railway carriage

: Figure 1 (a) & (b) show some preliminary drawings of a passenger railway carriage that was supplied to a design engineer to confirm the thickness of Aluminium sheets needed to fabricate the superstructure of the carriage.

|

|

What is the best the manufacturer can do in the instance

: What is the best the manufacturer can do in this instance? Assume that the manufacturer can tailor a take-it-or-leave-it offer for each individual retailer, of any form desired.

|

|

Use newton''s method with the specified initial approximation

: Use Newton's method with the specified initial approximation x1 to find x3, the third approximation to the root of the given equation. (Give your answer to for decimal places.)

|

|

Prepare journal entries for items a and j

: For items (a) and (j), analyze the amount and direction (1 or 2) of effects on specific financial statement accounts and the overall accounting equation. Prepare journal entries for items (a) and (j). Show how Accounts Receivable, Notes Receivable, a..

|

|

What are the highest and lowest values of its acceleration

: The location (as a function of time) of a car, moving in a straight line, is given by the expression x(t)= 2t + sin(2pi t)for [0,1]. What are the highest and lowest values of its acceleration in that time interval?

|