Reference no: EM132573585

MP4701 Design And Operation Of Sustainable Systems - University of Central Lancashire

Learning outcome 1. Design a bearing assembly that minimises friction and wear.

Learning outcome 2. Perform qualitative and quantitative analysis on mechanical systems.

Learning outcome 3. Design a complete conditioning monitoring system for a machine using ISO standards.

Learning outcome 4. Design of complete structural health monitoring system using SAE/ ISO standards.

Learning outcome 5. Analyse a design for its reliability and maintainability using ISO standard techniques.

DESIGN AND OPERATION OF SUSTAINABLE SYSTEMS

Ford Motors is planning to introduce a new model to address urban transportation challenge by investing in the emerging mobility service with the generation of cleaner vehicles and sustainable urban logistics. You have been asked to design the bearing for the rear wheels and the suspension system of the New Ford Tourneo Connect.

There is a trade-off with the size of the bearing, the size should be big enough to last 20 years and small enough to reduce the frictional power losses.

This is an open assignment, so the result and viability of the bearings is not known.

ASSIGNMENT OBJECTIVES:

» To design and select materials for a reliable shaft/bearing assembly that can be used for the above mechanical structure and minimises friction, wear and maintenance.

» To construct a reliability block diagram (RBD) analysis for the New Ford Tourneo Connect model and perform failure mode effects analysis (FMEA) for the same model.

» To propose a monitoring system (sensory- actuation system) that can be used to monitor system operational condition and prevent system/ sub-systems failure.

ASSIGNMENT BRIEF:

As an engineer in the ‘Ford Motors' company you have been asked to design the bearing for the rear wheel and suspension system. In addition to the bearing design you are also requested to construct a reliability block diagram, perform FMEA analysis and propose a monitoring system for the above prototype. The design process should take into consideration the main dimensions of the mechanical structure and materials of the shaft and bearings. You will need to estimate the size and weight of the rear wheel and to make realistic assumptions about the driving speed and suspension system.

Provide a detailed, professional report that contains the following items mentioned below:

1. Selection of dimensions of rear wheel and estimation of the torque, speed and power. Define the design parameters and state any required assumptions.

2. Selection of bearing diameter. You will need to justify your selection. Selection of bearing (diameter/width), calculation of forces and pressure on the bearing.

3. Look through different online resources to find the failure data for various components of the New Ford Tourneo Connect model. Construct a reliability block diagram (RBD) analysis for the rear wheel and suspension system of the New Ford Tourneo Connect model. List out all the assumptions you have made in the construction of the RBD (e.g. failure criteria, failure/repair interval, maintenance strategy, etc.)

4. Perform the failure mode effects analysis (FMEA) on the New Ford Tourneo Connect model. Discuss and compare the salient features of similarities and differences of the quantitative method like RBD over qualitative method like FMEA.

5. Propose a monitoring system (sensory- actuation system) that can be used to:

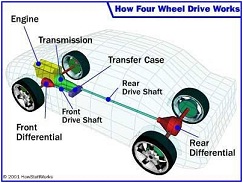

- Monitor the operating condition of the car transmission

- Predict the failure transmission elements.

Describe in detail the main elements of the system. Use block diagrams to support your discussion.

Attachment:- Design And Operation Of Sustainable Systems.rar