Reference no: EM132539404

MECH0018 Stress Analysis - Middle East College

Learning Outcome 1: Critically evaluate the implications of the theories of elastic and plastic fracture mechanics and apply these to simple problems.

Learning Outcome 2: Review the applications of the linear Theory of Elasticity, Theory of Plasticity and Fracture Mechanics to practical design problems and identify the limitations of these theories.

Assignment Objective

The main objective of this assignment is to develop the students' understanding of stress analysis, behavior of materials and finite element solution procedures, thus enabling them to select and apply concepts creatively in the solution to complex problems of stress analysis in design.

Problem 1:

(A) The ductile behaviour of a certain metal is well described by σ = 90000ε0.25. The metal undergoes uniform work hardening process to a reduction in area of r = 40%, find the yield stress of the work-hardened metal.

(B) If the metal in (A) above, governed by the same ductile behavior equation, is cold-worked first by 30% which is still followed by an additional cold work of 35%, find the yield stress of the metal.

(C) Provide your comment(s) why the yield stresses in Q4A and Q4B are not the same.

(D) If a bar of same metal of (A) above is initially cold worked some unknown amount. It is then subjected to 20% additional cold work and its yield strength is measured as 78,541 n/m2. What was the unknown amount of cold work induced prior to the 20% added cold work?

Problem 2:

(A) A 65.4 mm wide aircraft inspection panel is made of 7074-T651 aluminium alloy. The material properties are (Fracture toughness, KIc = 25.8 MN m-3/2 and Yield stress, σy = 505 MPa. Following inspection, an edge through-crack, a, of length 6.4 mm is found. During flight, this plate is subjected to a cyclic stress of 90 MPa. Ignoring the effect of the mean stress, calculate the number of cycles to failure (Nf) using Paris' Law and the material constants (in their standard units): A = 1.5x10-12 m/(MNm-3/2)n per cycle and m = 2.8, (Take Y = 1.12)

(B) Discuss the effect of the fracture toughness KIc if its value reduced to be 20 MN m-3/2

(C) Differentiate between the stress concentration factor, toughness, and stress intensity factor.

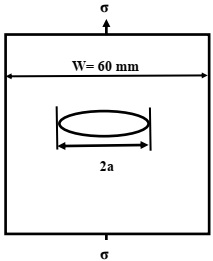

Problem 3:

A 60 mm wide sample plate of 7074-T8 aluminium alloys is shown in Fig. 1 and it contains a central crack length, 2a, and fracture toughness, Kc = 22,200,000 Nm-3/2 and the yield strength, σy = 520,000,000 N/m2.

(A) If the applied stress, σ = 150,000,000 N/m2, determine if the plate will fracture for a crack half-length of 6 mm, and 8 mm.

(B) Determine the critical half crack-length, ac, below which the plate will fail by yielding (Take Y = 1).

(C) Discuss the following categories of Stress-Strain Relationship in details:

- Perfectly elastic

- Elastic and perfectly plastic

- Elastic and strain hardening

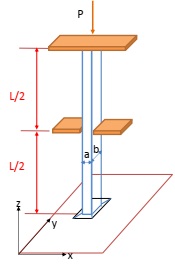

Problem 4:

The vertical rectanguler cross section column shown in Fig. Q4 is pinned at both ends. Assuming the young's modulus E for the column material is 200 GPa, σy = 250 MPa, L = 4 m, a = 30 mm, and b = 50 mm:

A) Find the maximum compressive load P that can be applied to the column without failure

B) Determine the allowable load.

C) Do you think this column will yield before it buckled? (Take FS = 2.5)

Fig. Q4: Rectangular Cross Section Column

D) What is the difference in the results of A, B, and C above if the column length is (L = 6 m)? Discuss the difference.

Attachment:- Stress Analysis.rar