Reference no: EM13342660

Manufacturing Planning

Suppose that you are the production manager of a product that your company manufactures. Particularly, a sub-product comes to your manufacturing department's buffer area initially. After that, this sub-product should go through two processes to become an end-product. First, it should go through process 1, and then it should go through process 2. There are different machines that can complete each process and each process can be completed by one machine.

- Process 1 (initial assembly) can be completed by machine A or machine B. Machine A can complete process 1 in 38 seconds. Machine B can complete process 1 in 34 seconds.

- Process 2 (final assembly) can be completed by machine C or machine D. Machine C can complete process 2 in 27 seconds. Machine D can complete process 2 in 24 seconds.

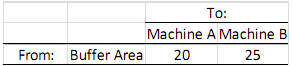

A sub-product in the buffer area, therefore, first should go to either machine A or machine B. The table below shows the time (in seconds) it takes a sub-product to be transferred to machine A or machine B from the buffer area.

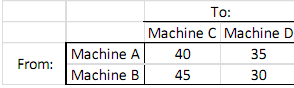

After process 1 is completed by machine A or machine B, the processed sub-product should go to either machine C or machine D for process 2. The table below shows the times (in seconds) it takes a sub-product to be transferred from machines A and B to machines C and D.

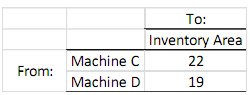

Finally, after process 2 is completed by machine C or D, the end-product should go to the inventory area. The table below shows the time (in seconds) it takes the end-product to be transferred from machines C and D to the inventory area.

As the production manager, you want to determine the manufacturing plan for the sub-product so that you can minimize the total time it takes a sub-product to go from the buffer area to the inventory area as an end-product.

In this problem, you are asked to formulate the above production planning problem as a network optimization problem.

a) Represent the above production planning problem on a network and state it as a network optimization problem (i.e., min-cost flow, shortest path, or max-flow). To do so:

- Define the nodes, what they represent, and node values if any.

- Define the arcs, arc costs, arc capacities if any.

- The network you defined should not have node capacities, node costs, and undirected arcs.

- State the problem as a network optimization problem using the network.

b) Mathematically formulate the above network optimization problem as a min-cost flow or max-flow problem (if you stated the problem as a shortest path problem, recall that shortest path problems can be formulated as min-cost flow problems). Define your decision variables clearly and the notation you use for your decision variables, write the objective and objective function, and constraints. Combine everything to get the final model (you should not have any constraints other than flow-balance, arc-capacity, and non-negativity constraints).

|

Evaluate the mass of water produced from 9.47g of methane

: Calculate the mass of water produced from 9.47g of methane, CH4, reacts with an excess of oxygen in the following unbalanced reaction. 2C8H18(g)+25O2(g)=16CO2(g)+18H2O(g)

|

|

Sending water through the pipe network

: Formulate a network optimization problem for transferring as much water as possible from the water depot to the fire district and how would you modify the above network and your model in part a so that you still only have flow balance and arc capa..

|

|

Evaluate the minimum number of grams of propane

: Calculate the minimum number of grams of propane,C3H8 (g) , that must be combusted to provide the energy necessary to convert 3.15kg of ice at -15.5degC to liquid water at 75.5degC. C3H8 (g)

|

|

Use strategic management principles and technologies

: generate, evaluate and use quantitative and qualitative information to measure financial and non financial performance of an organisation.

|

|

Manufacturing planning

: Define the nodes, what they represent, and node values and define the arcs, arc costs, arc capacities if any.

|

|

Define your decision variables and the notation

: find the optimum solution or optimum solutions. Does the model have infeasibility, unique optimum, alternative optima, or unboundedness?

|

|

Problem on managerial accounting

: Using the articles supplied as a BASE for your research, you are to find at least TWO examples of business entities that are applying these principles in their operations and write a report on the success (or failure) of the adoption of these prin..

|

|

Explain three reactions and their corresponding values of gº

: Consider these three reactions, and their corresponding values of ?Gº: 1/2 N2 + O2 NO2 ?Gº = 100 kJ 2 NO2 2 NO + O2 ?Gº = 200 kJ NOBr NO + 1/2 Br2 ?Gº = 300 kJ Calculate the value of ?Gº for 1/2 N2 + 1/2 O2 + 1/2 Br2 NOBr.

|

|

Formulate a linear programming model

: Determine how to load each truck by deciding on how many units of the product will be delivered to each by each truck. While doing so, you need to make sure that each store is delivered with exactly the number of units of the product they require.

|