Reference no: EM132483321

Project - Life assessment of high temperature header piping and tube system

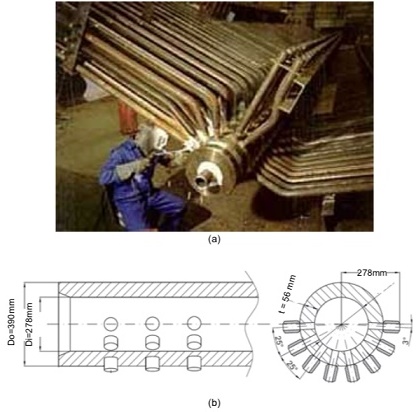

The project aims for a life assessment of a high temperature steam header piping and tube system at a power generation plant. The client has requested a life assessment to be performed on one of their superheater header, as shown in Figure 2.1, which is a central manifold for other piping runs that is used to convert saturated or wet steam into superheated or dry steam.

The plant is considering to change its operation mode to a two-shifting mode. where the plant will be shut down over the weekend (Friday night at 8pm) and restarts the operation back on Monday at 8am. The header has experienced some 82000 hours operation already.

Using pressure vessel design codes such as the EN12952 or ASME 831.1, estimate the remaining fatigue and creep life of a header with a stub configuration, as shown in Figure 2.2 if the two-shifting mode is to be run. They would also like to understand the geometrical effects of a row of tubes/stubs on the stress in the header and to estimate the fatigue and creep life of the header. These effects are taken into account through the parameter VL called ligament efficiency. The main dimensions of the component and operating conditions are reported in Table 1.

The owner of the plant welcomes recommendations with respect to header maintenance following the proposed change in operation as well as improvements in the design, optimisation of materials and manufacturing of the steam header piping and tubing.

Fig. 2.1. (a) A superheater header being manufactured (b) the geometry of the header with tubes.

Table 1: Nominal dimensions & Operating conditions

|

Material

|

Header

|

21/4CrMo

(P22)

|

|

Tube

|

|

Geometry

|

Header outer diameter D., mm

|

390

|

|

Header thickness, t, mm

|

56

|

|

Tube stub outer diameter d., mm

|

57

|

|

Tube thickness 1., mm

|

9

|

|

Pitch between tube holes L1, mm

|

336

|

|

Pitch between tube holes L2, mm

|

400

|

|

Operating condition

|

Pressure P, MPa

|

14

|

|

Temperature T, °C

|

565

|

|

Total in-service time, hrs

|

82000

|

Literature review (including review on methods and data search, references to standards/codes)

Quantitative (analytical and/or numerical) analysis including evidence of work, the justifications and the discussion

Conclusion and Recommendation (consideration can be on the Materials, Manufacturing, Design, Operation and/or Maintenance)

Report presentation & quality