Reference no: EM133081744

Inventory and Operations Management (IOM)

Harvey Industries Case Study

Assignment task

The company has approached you as a consultant to prepare a report with recommendations on how to improve its inventory management and assembly process planning that were raised as the root cause. The total word count for this group report is STRICTLY limited to 1500. As the audience would be a business, the report must be concisely written. The main body of the report should cover the following questions:

Question 1: Critically analyse the situation at Harvey Industries with a view to supporting a recommendation for an improved inventory management and assembly planning solution.

Question 2: What would you recommend to Harvey Industries to elevate its inventory management efficiency? This might include aspects such as, but not limited to, inventory control, procedures and software, cycle stock and safety stock, service level, lead time, and operation/maintenance costs.

Support your solution with a diagram to show identified effects/causes and the proposed solutions.

Your recommendations should clearly demonstrate how they would work in practice.

Question 3: Discuss the advantages/disadvantages of recommending (1) enhanced forecasting; and (2) a higher inventory level.

Question 4: How would guide the production manager to have a more robust assembly short-term planning and control process that would help in overcoming longer lead time and reduce the possible turbulence in the assembly process?

Question 5 to Question 7 are calculation-based questions. In answering these questions, write down all the equations and identify input parameters used for calculation and where appropriate please include carefully labelled figures and tables. Ensure each equation, figure and table is numbered, has a meaningful heading and that all axes are clearly labelled. Note that there is no word count questions 5-7.

Question 5: The purchasing manager is seeking to keep single sourcing for the high-pressure gun hook.

a. Which of the two vendors would you recommend him to keep and in what order size? Justify your answer.

b. At what point (ROP) the purchasing team should reorder, targeting a service level of 95%?

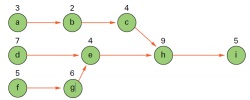

Question 6: The case company plans to rebalance the assembly line for one of the units towards higher productivity. Figure 1 shows the precedence diagram for its assembly tasks (times are in minutes).

The aggregate planner specifies a production target of 40 units per full day; however, the assembly line would work for only 9.333333 hours per day.

Figure 1. Precedence diagram for the considered unit.

Your role hereby is to recommend the optimal number of workstations and associated tasks for each workstation towards efficient utilization of resources. You may primarily use the most following rule and, if needed, use the greatest positional weight as a tiebreaker.

Question 7: The production team has received orders (in units) for the next six months for two sizes of car wash systems as show in Table 2.

Table 2. Orders related to Sizes 1 & 2 of a unit for the next six months.

Feb Mar Apr May June July

|

Size 1

|

1,000

|

900

|

600

|

700

|

1,100

|

1,100

|

|

Size 2

|

500

|

500

|

300

|

500

|

400

|

600

|

a. Would you advise the aggregate planner to develop one plan, instead of two, for these two sizes of units? If so, when this might be possible? Clarify your answer verbally without calculations.

b. Towards a better usage of the skilled workers, the production manager aims to have a stable maximum output level. The team has exhausted all inventory on hand by the end of January; but, the production manager would prefer to have 300 unit on hand at the end of July. Develop a unified (i.e., just one) level production plan for the two sizes of that unit, that shows the total plan costs, based on the forecast presented in Table 2. It should be noted that a maximum space of 200 units/month as back orders is available.