Reference no: EM132705505

MP4702 Advanced Materials and Materials Selection - University Of Central Lancashire

Learning Outcome 1: Able to communicate effectively on material selection with material scientists

Learning Outcome 2: Able to understand the implications of different modes of material failure

Learning Outcome 3: To understand the effects of composition and heat treatment on the properties of different types of material

Learning Outcome 4: To select materials to minimise the likelihood of component failure

QUESTION 1

Spirotech Group Limited have been leading pressure vessel manufacturers in United Kingdom and chemical holding tank suppliers for both the refrigeration, oil and gas sectors for over 35 years. Spirotech Group Limited in-house design department work closely with their customers to ensure they get the right pressure vessels for the intended application. Spirotech Group Limited is planning to expand their business into other sectors such as food processing, nuclear and water industries. As a design engineer of the Spirotech Group Limited company you have been asked to design a pressure vessel for the food manufacturing industry and the designed pressure vessel should be as cheap as possible. The main objective of the work is to select a suitable material for the outer wall of the pressure vessel for two configurations as shown in Figure Q - 1. When the pressure vessel is fully assembled it resemble as a (i) cylindrical shape with both ends open having an external pressure, p and (ii) spherical shape having an external pressure, p.

Figure Q - 1: Pressure Vessels

The design of the outer wall of the cylindrical/spherical pressure tank and the selected material should resist the external pressure, p. The radius of the pressure tank is 5 m. The outer wall containing the pressure, p should not fail either by yielding or by buckling or by fast fracture. The size of the possible largest crack contained in the outer wall is ac.

Materials properties that are available for ranking materials are: density (ρ); Yield strength (σy); Critical stress intensity factor or fracture toughness of the material (KIC).

You will need to decide your own dimensions, extra constraints and find out the equations for yielding, buckling and fast fracture of the pressure vessel. In order to translate the right material selection for the food processing application into a real engineering problem you need to answer the following questions:

PART - I

(i) Cylindrical shaped pressure vessel with both ends opened

(a) Translation of problem indicating function, objective, constraints and free variables?

(b) Derive the performance material index for failure.

(c) Discuss the implication of two performance index i.e., due to yielding and fast fracture for the selection of one material. Find the coupling line by making equal the cost calculated with the two indexes.

(d) Use CES EDUPack (Rebranded as GRANTA EDUPACK 2020) to create a graph representing the material index and identify the region of the chart with the cheapest materials for the pressure vessel due to yielding and fast fracture material index.

[Hint 1]: Use the concept of coupling line for selecting best material materials for the cylindrical pressure vessel due to yielding and fast fracture material index.

PART - II

(ii) Spherical shaped pressure vessel

(e) Translation of problem indicating function, objective, constraints and free variables?

(f) Derive the performance material index for failure.

(g) Use CES Edupack (Rebranded as GRANTA EDUPACK 2020) to create a graph representing the material index and identify the region of the chart with the cheapest materials for the for the pressure vessel due to fast fracture material index.

Reminder, as it is an open exercise, each student is expected to have a unique solution as definition of the problem will be unique.

QUESTION 2 PART - I

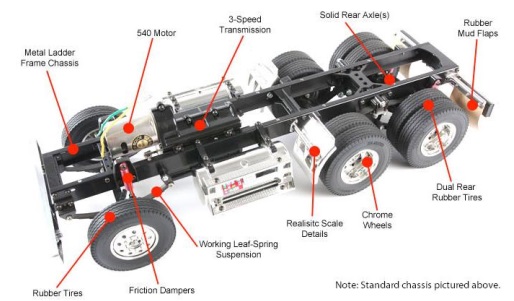

A truck manufacturing company wants to design a new material for the springs used in the heavy loaded trucks (Figure Q - 2). In vehicle suspension design it is desirable to minimize the mass of all components and select a material as cheap as possible. You have been asked to select a material and dimensions for a light spring to replace the steel leaf-spring of an existing truck suspension. You need to decide the structure of the existing leaf-spring. The new spring must have the same length, L and stiffness, S as the existing one, and must deflect through a maximum safe displacement, δmax without failure.

Figure Q - 3 : Vehicle suspension system

You will need to decide extra constraints and find out the necessary equations to solve the springs for truck application. You will need to decide your objective and to compare the results with real world materials. You will need to translate the problem, derive the performance index or indexes, coupling line between the performance index and select some screening constraint.

[Hint 1]: You will have to decide your own dimensions for the selected structure and the constraints.

You have to document the whole selection process.

(a) Definition of the problem

(b) Translation of the problem

(c) Derive performance index

(d) Use CES Edupack (Rebranded as GRANTA EDUPACK 2020) to create a graph representing the material index and identify the region of the chart with the cheapest materials for the leaf spring.

PART - II

Most of the springs are made of high strength alloy steel, and they are heavy. You are asked to explore the potential of alternative materials for lighter springs, recognizing there must be a trade-off between mass and cost - if it is too expensive, the manufacturing company will not want it even if it is lighter.

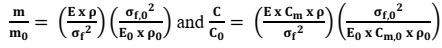

Show that the mass and material cost of the spring relative to one made of high strength alloy steel is given by

where ρ is the density, σf the failure strength and Cm the cost per kg of the material, and the subscript "o" indicates values for high strength alloy steel.

[Hint 2]: Use the ratio for new material over the steel.

(e) Show that the mass and material cost of the spring relative to one made of high strength alloy steel is given by

(f) Explore the trade-off between relative cost and relative mass. Sketch a trade-off surface. Define a relative penalty function.

Reminder, as it is an open exercise, each student is expected to have a unique solution as definition of the problem will be unique.

QUESTION 3

(a) Draw the Time Temperature Transformation T-T-T diagram for Aluminium - Copper (Al - 4 % Cu) alloys and show on the diagram the critical cooling curve, the transformation lines, the phases and the axis.

(b) Explain the change of structure with martensitic transformation of steels.

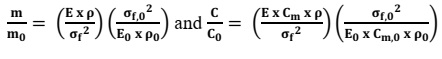

(c) The copper-tin system (which includes bronzes) is shown in the Figure Q - 3 below

Figure Q - 3: Copper - Tin phase diagram Note: Use the Annexure 1 for calculations

(i) List and mark out the single phase regions;

(ii) Highlight the four eutectoids in the copper-tin system,

(iii) List out the compositions and temperatures of the eutectoids.

(iv) Discuss with help of simple sketch along with an example of the phase diagram (binary system) in which PERITECTIC REACTION AND PERITECTIC POINT, reaction occur during the phase transformation of metals. Describe the phase reaction and the corresponding temperature for the selected example.

(d) Compare and contrast the main features of diffusive and displacive transformations during structural changes in metals.

QUESTION 4

Houses in UK uses cast iron or steel guttering and this gutter material is prone to corrosion over time as shown in Figure Q - 4.

(i) To prevent the mild sheet-steel guttering from corrosion it is copper-plated and the guttering acts as a drain for sea water. If the coating is damaged, exposing the steel, will the guttering corrode in a damaging way?

(ii) If instead the guttering is zinc-plated, will it be better or less well protected?

Suggest the mechanism of corrosion taking place in these two types of coating on the mild sheet-steel guttering.

Figure Q - 4: Corrosion of steel gutter

QUESTION 5

(a) Using suitable examples, explain the meaning of dislocation movement in metals. Explain with simple sketches different types of dislocation in relation to metals.

(b) Using suitable industrial examples, explain creep in metals. Comment and contract dislocation movement in both plastic deformation and in creep.