Reference no: EM1332688

Question 1: Maintenance at a major theme park in central Florida is an ongoing process that occurs 24 hours a day. Since it is a long drive from most residential areas to the park, employees do not like to work shifts of fewer than eight hours. These 8-hour shifts start every four hours throughout the day. The number of maintenance workers needed at different times throughout the day varies. The following table summarizes the minimum number of employees needed in each 4-hour time period.

Time Period Minimum Employees Needed

12 AM to 4 AM 90

4 AM to 8 AM 215

8 AM to 12 PM 250

12 PM to 4 PM 165

4 PM to 8 PM 300

8 PM to 12 AM 125

You are the maintenance supervisor for the theme park. How will you schedule the employees? Formulate an LP model for this problem and solve it using Solver. What is the optimal solution?

Question 2: Virginia Tech operates its own power generating plant. The electricity generated by this plant supplies power to the University and to local businesses and residences in the Blacksburg area. The plant burns three types of coal which produce steam that drives the turbines that generate electricity. The Environmental Protection Agency (EPA) requires that for each ton of coal burned, the emissions from the coal furnace smoke stacks contain no more than 2500 parts per million (ppm) of sulfur and no more than 2.8 kilograms of coal dust. The following tables summarizes the amounts of sulfur, coal dust, and steam that result from burning a ton of each type of coal.

Coal Sulfur Coal Dust Pounds of Steam Produced

(in ppm) (in kg)

1? 1100 1.7 24,000

2? 3500 3.2 36,000

3 2700 2.4 28,000

The three types of coal can be mixed and burned in any combination. The resulting emission of sulfur or coal dust and the pounds of steam produced by any mixture are given as the weighted average of the values shown in the table for each type of coal. For example, if the coals are mixed to produce a blend that consisted of 35% of coal 1, 40% of coal 2, and 25% of coal 3, the sulfur emission (in ppm) resulting from burning one ton of this blend is:

0.35* 1100 + 0.40 * 3500 + 0.25 * 2700 = 2460

The manager of the facility has asked you, the analyst, to determine the blend of coal that will produce the maximum pounds of steam per ton without violating the EPA requirements.

Formulate an LP model for this problem. Create a spreadsheet model for this problem and solve it using Solver. What is the optimal solution?

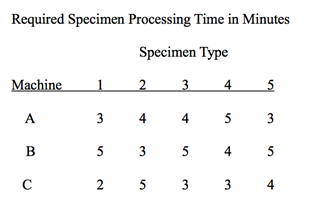

Question 3: Radmore Memorial Hospital has a problem in its fluid analysis lab. The lab has available three machines that analyze various fluid samples. Recently, the demand for analyzing blood samples has increased so much that the lab director is having difficulty getting all the samples analyzed quickly enough and still completing the other fluid work that comes into the lab. The lab works with five types of blood specimens. Any machine can be used to process any of the specimens. However, the amount of time required by each machines varies depending on the type of specimen analyzed. These times are summarized in the following table.

Required Specimen Processing Time in Minutes Specimen Type

Each machine can be used a total of 8 hours a day. Blood samples collected on given day arrive at the lab and are stored overnight and processed the next day. So at the beginning of each day the lab director must determine how to allocate the various samples to the machines for analysis. This morning the lab has 80 type 1 specimens, 75 type 2 specimens, 80 type 3 specimens, 120 type 4 specimens, and 60 type 5 specimens awaiting processing. The lab director wants you to to determine how many of each type of specimen should be analyzed on each machine.

Formulate an LP model for this problem. Create a spreadsheet model for this problem and solve it using Solver. What is the optimal solution?