Reference no: EM131306173

Air Quality Engineering Assignment

Problem 1

Plot the ambient air temperature profile for the following data.

|

Altitude (feet)

|

Air Temp (oF)

|

|

0

|

56.5

|

|

250

|

58.0

|

|

500

|

60.3

|

|

750

|

61.5

|

|

1 000

|

62.0

|

|

1 250

|

62.0

|

|

1 500

|

61.6

|

|

1 750

|

61.2

|

|

2 000

|

60.8

|

a) For the altitude between 500 feet and 1 000 feet, what is the lapse rate and is the lapse rate greater or less than the DALR?

b) For the altitude between 1 500 feet and 2 000 feet, what is the lapse rate and is the lapse rate greater or less than the DALR?

c) What is the stability condition of the between ground level and 500 feet?

d) If air on the ground is heated to 62oF, how high would it rise under this temperature profile condition (what is its mixing height)?

Problem 2

A soil contaminated with 100 mg metals/kg of soil, 50,000 mg S/kg of soil, 1,000 mg F/kg of soil and 40,000 mg Cl/kg of soil, is to be treated using an incinerator. The incinerator is operated at a heat load of 63 MM Kilojoules/hour and has an estimated stack gas flow of 986 m3/minute and the feed rate of the soil into the incinerator will be 3,400 g of soil/hour. Using the EPA uncontrolled source emission factors given below, estimate the hourly emissions that would be expected in the flue gas of this incinerator if no air pollution control equipment were used.

|

Pollutant

|

Emission Factor

|

|

VOCs

|

0.1 g VOCs / kg VOC in waste soil feed

|

|

Metals (total)

|

50.0 g metals / kg metals in waste soil feed

|

|

HCl

|

1.03 g HCl / g Cl in waste soil feed

|

|

HF

|

1.05 g HF / g F in waste soil feed

|

|

SO2

|

2.00 g SO2 / g S in waste soil feed

|

|

PM

|

11,750 mg PM / m3 of flue gas

|

|

CO

|

0.05 kg CO / MMKJ

|

|

NOx

|

0.15 kg NOx / MMKJ

|

Problem 3

An office park complex operates and maintains numerous hot water boilers within its various buildings. Although this complex has conducted emissions inventories and reported emissions for several years, it has never attempted to quantify the emissions resulting from these boilers. All boilers are natural gas fired and are uncontrolled (no pollution control equipment is used). The following boilers represent the three different types of boilers that are used. Using emission factors that you find in EPA's AP-42 documents, calculate the annual emissions that occurred from these three boilers (Note: In order to calculate the emissions from all boilers located within this complex, the approach for these three boilers would need to be applied to the remaining boilers and their operating data.).

|

|

Boiler #10

|

Boiler #12

|

Boiler #30

|

|

Annual Fuel Consumption (MSCF)

|

67, 959

|

1,006

|

1,375

|

|

Hours of Operation

|

4,643

|

5,400

|

8,760

|

MSCF = 10

6 standard cubic feet

The design capacities of boilers #10, #12, and #30 are 61.2 MMBtu/hr., 3.6 MMBtu/hr., and MMBtu/hr., respectively.

Problem 4

An oil refinery currently has one stack (Stack 1) emitting sulfur dioxide. The level of exposure to nearby populations from the sulfur dioxide emissions is not known. The facility would like to determine the potential impact of its emissions on various downwind receptors and to identify a monitoring site location that could possibly measure the maximum occurrence of a downwind sulfur dioxide concentration at ground level. This facility is the only known source of sulfur dioxide in the region.

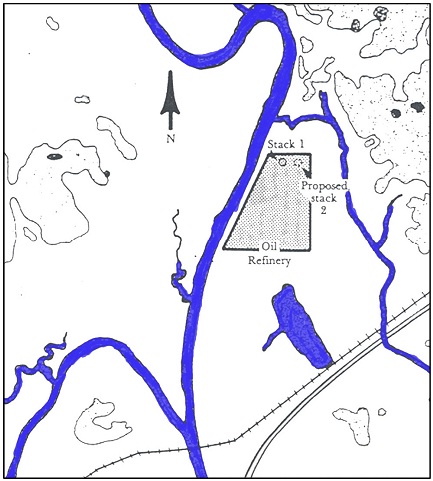

The refinery is located in a rural area (see the generalized figure included), and is situated in a river valley with relatively flat terrain. A river runs northeast to southwest along the western boundary of the refinery, and a small lake is located just south of the refinery. A major four- lane highway and a railroad serve the area and run northeast to southwest. The populations living nearest to the refinery include the following:

1) Small town located 1.5 km east of the existing refinery stack 1

2) Farm located 950 meters directly to the west of the existing refinery stack 1

3) Summer camp facility at the small lake located 540 meter to the south of the existing refinery stack 1

Stack 1 currently emits sulfur dioxide at a rate of 4.78 grams per second. This stack is 35.0 meters high and has an inside diameter of 1.56 meters. The stack gas velocity is 13.2 meters per second, and stack gas temperature is 394 Kelvin. The stack is located 10 meters from the north property boundary, 33 meters from the west property boundary, 160 meters from the south property boundary, and 60 meters from the east property boundary.

The average annual ambient temperature is 18.3oC.

During different months of the year, the predominant wind direction, average wind speed (at 10 meters) and the typical stability characteristics are shown in the following table.

|

Month

|

Wind Direction

|

Wind Speed (m/s)

|

Stability Class

|

|

January

|

NNW

|

3

|

D

|

|

February

|

N

|

3

|

E

|

|

March

|

W

|

6

|

D

|

|

April

|

SW

|

4

|

C

|

|

May

|

SW

|

3

|

C

|

|

June

|

S

|

4

|

B

|

|

July

|

SSW

|

4

|

B

|

|

August

|

SW

|

2

|

A

|

|

September

|

SSE

|

4

|

B

|

|

October

|

E

|

4

|

D

|

|

November

|

NW

|

3

|

D

|

|

December

|

NNW

|

2

|

E

|

Use the AJ Designer Dispersion model (used in HW #4) with the method referred to as "Method 1" to calculate the sigma-y (σy) and sigma-z (σz) dispersion coefficients, and determine the following:

1) Which receptor appears to experience the highest concentration of sulfur dioxide?

2) How far downwind from the stack would be a good location to place an SO2 monitor if you wanted to be able to measure the highest concentration of SO2 occurring in the month of February?

Figure for Problem 4. Generalized location of oil refinery and its immediate surroundingarea. The proposed stack #2 is not being considered in problem 4.