Reference no: EM133172924

Task 1 Civil Works Design

You are required to undertake a civil construction design project as outlined below. Your Assessor will take the role of the client for the purposes of this assessment task.

Design Specifications

1. The Problem

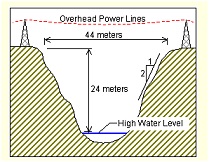

You are a civil designer working for the state department of transportation. You have been assigned responsibility for the design of a truss bridge to carry a two-lane highway across the river valley shown below.

2. Design Objective

Satisfy all of the specifications listed below, while keeping the total cost of the project as low as possible.

3. Bridge Configuration

1. The bridge may cross the valley at any elevation from the high water level to 24 meters above the high water level.

2. If the elevation of the bridge is below 24 meters, excavation of the river banks will be required to achieve the correct highway elevation.

3. To provide clearance for overhead power lines (shown above), the highest point on the bridge may not exceed an elevation 32.5 meters above the high water level (8.5 meters above the top of the river banks).

4. The bridge may consist of either standard (simple supports) or (arch supports). If necessary, the bridge may also use one intermediate , located near the centre of the valley. If necessary, the bridge may also use cable , located 8 meters behind one or both abutments.

5. Each main truss can have no more than 100 and no more than 200 .

6. The bridge will have a flat, reinforced deck. Two types of concrete are available:

1. Medium-strength concrete requires a deck thickness of 23 centimetres (0.23 metres).

2. High-strength concrete requires a deck thickness of 15 centimetres (0.15 meter).

7. In either case, the deck will be supported by transverse spaced at 4 metre intervals. To accommodate these floor beams, your must have a row of joints spaced 4 meters apart at the level of the deck. These joints are created automatically when you begin a new design.

8. The bridge deck will be 10 meters wide, such that it can accommodate two lanes of traffic.

4. Member Properties

• Materials. Each member of the truss will be made of either carbon steel, high- strength low-alloy steel, or quenched and tempered steel.

• . The members of the truss can be either solid bars or hollow tubes. Both types of cross-sections are square.

• Member Size. Both cross-sections are available in a variety of standard sizes.

5. Loads

The bridge must be capable of safely carrying the following loads:

• Weight of the deck.

• Weight of a 5-cm thick , which might be applied at some time in the future.

• Weight of the steel floor beams and supplemental bracing members (assumed to be 12.0 applied at each deck-level joint).

• Weight of the main trusses.

• Either of two possible truck loadings:

• Weight of one standard H25 truck loading per lane, including appropriate allowance for the dynamic effects of the moving load. (Since the bridge carries two lanes of traffic, each main truss must safely carry one H25 vehicle, placed anywhere along the length of the deck.)

• Weight of a single 480 kN Permit Loading, including appropriate allowance for the dynamic effects of the moving load. (Since the Permit Loading is assumed to be cantered laterally, each main truss must safely carry one-half of the total vehicle weight, placed anywhere along the length of the deck.)

6. Structural Safety

The bridge will comply with the structural provisions of the state specified standards, to include:

• Material densities

• Load combinations

• Tensile strength of members

• Compressive strength of members

7. Cost

The cost of the design will be calculated using the following cost factors:

• Material Cost:

• Carbon steel bars - $4.50 per kilogram

• Carbon steel tubes - $6.30 per kilogram

• High-strength steel bars - $5.00 per kilogram

• High-strength steel tubes - $7.00 per kilogram

• Quenched and tempered steel bars - $5.55 per kilogram

• Quenched and tempered steel tubes - $7.75 per kilogram

• Steel Production(fabrication) Cost: $1000.00 per each steel pattern

• Connection Cost: $500.00 per joint

• Site Cost:

Required:

Part 1: (Design Analysis)

• Reinforced concrete deck (medium strength) - $5,150 per 4-meter panel

• Reinforced concrete deck (high strength) - $5,300 per 4-meter panel

• Excavation - $1.00 per cubic meter (See the Site Design Wizard for excavation volume)

• Supports (abutments and pier) - Cost varies (See the Site Design Wizard for specific values)

o $6,000 per anchorage

Refer to design model 1 document. Given the below forces:

Determine the horizontal and vertical components of reaction at the support.

Determine the forces in members 17, 19, 20, 16 and 21. State if the members are in tension or compression. Note that all angles are 45 degrees.

Part 2: (Estimation)

1. Make a detailed list of all constraints and requirements to the bridge design.

2. Three different materials available for the design of the bridge:

• Carbon steel,

• High-Strength Low-Alloy steel and

• Quenched and Tempered Low-Alloy Steel

Describe the differences between these materials. Which material is the best choice for a given structural design?

3. One of the most important decisions in the bridge design is the selection of a cross- section type, solid bar or hollow tube, for each member in the structural model.

At what locations should each type of cross section be used? (Hint: you should consider the effect of the different cross-sections on member strength in both tension and compression.)

4. A good engineer will try to find the best balance between the site cost (such site excavation, adding piers or cables) and the truss cost. Explain what is meant by this statement and provide some examples.

5. You are given two proposed designs that meet the design specifications. Estimate the total cost for each design and accordingly provide a recommendation on which model is more economical.

6. For each design model, address its environmental impact on the surroundings such as the river channel.

7. Based on all your analysis (cost + environmental), which is the optimum design?

8. Perform a risk assessment for the project taking into account all lifespan stages:

• the existing conditions

• the application of the design

• maintainability of the works

Attachment:- Civil Works Design.rar