Reference no: EM131040031

Assignment 1: Manufacturing and Design

The work should include excel sheets for the calculations and SolidWorks modeling and drawing.

(Design and Manufacturing Project)

Each group is a separate company and each group/company will provide its independent proposal with detailed required all in a hard copy with all images in Tiff, Jpeg or pdf format, along with tables, graphs used , and graphs generated , as well as calculations using relevant equations , web links for information used, all integrated in typed (Both MS Word and pdf versions ) report. This report will be graded and accompanying CD should provide all source files, calculations spread sheets, graphs data, Solid Work Drawings and 3D solid models and any simulation/animation files.

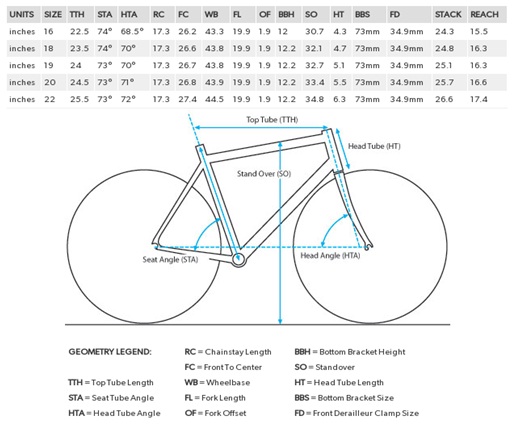

Provide manufacturing details for making a frame for a commuter bicycle with size 22, dimensions shown in Figure 1. The required details are

1- The frame is to support a rider weight of 100 kg.

2- Material of the frame is to be from fiber reinforced composite.

3- Provide type of matrix and fiber with fiber volume fraction. Provide analysis used to choose volume fraction. If computer model is used for analysis then present it.

4- Describe using sketches the needed manufacturing steps. State tooling needed and estimated time for each step.

5- Estimate the cost of the bicycle frame.

6- Describe design modification that might be needed due to choosing fiber reinforced composite to make the bike. Provide engineering drawing to illustrate these modifications. Drawings for parts (with tolerances) and assembly are to be provided on different pages.

7- Describe safety and environment impact as a result of the manufacturing processes selected.

Assignment 2: Statistics In Manufacturing

Q1 Regression Analysis

Q2. A highly automated factory is producing ball bearings. The average ball diameter is 0.2152 in and the standard deviation is 0.0125 in. These dimensions are normally distributed.

1. What percentage of the parts can be expected to have a diameter less than 0.2500 in?

2. What percentage of the balls are between 0.2574 and 0.2512 in?

Q3. (a) The lifetime of a mechanical switch produced by a company has been determined to have a population mean of μ = 2000 h and σ = 200 h. The temper of a phosphor bronze leaf spring in the switch is changed slightly by the supplier. To determine whether this has changed the product, a sample of 100 switches is tested to give the sample values x ¯=1960and s=180. Has there been a change in the product?

Q4. A vendor of steel wire advertises a mean breaking load of 10,000 lb. A sample of eight tests shows a mean breaking load of 9250 lb and a standard deviation of 110 lb. Do our tests support the vendor's claim?(0.75 point)

Q5. The manager of a quality-control lab is concerned with whether two stress rupture machines are giving reliable results. Six specimens of the same material are run on each machine at the same temperature and stress level. The logarithm of the rupture time is used as the test response. The results for the two machines are:

Does the manager have cause for concern?

Q6. The following data were obtained for the transverse reduction of area (RAT) of a steel gun tube (Embed your excel sheet in the solution document, and show the graphs)Use Excel

(a) Plot a frequency histogram from these data

(b) Plot the cumulative frequency distribution on regular coordinate paper.

(c) Determine the mean, median, and mode.

(d) Determine the range and standard deviation

(e) Plot the cumulative frequency distribution on normal-probability paper, and determine the mean and standard deviation.

Q7 .For the data given in Q6.

(a), What are the 95 percent confidence limits on the mean of the population?

(b) What are

Q8.Eight fatigue specimens were tested at the same stress. The number of cycles to failure, expressed as log N, were as follows.

What is the mean fatigue life and its standard deviation?

Three blocks are to be assembled as shown in Fig. P4-l.

(a) Determine the average size and the bilateral tolerance of dimension A that results, based upon the combinations of extreme possible conditions.

(b) Using a statistical approach, determine the bilateral tolerances expected for dimension A.

I. Refer to Fig. 4-2 in the text. Suppose dimensions A. B. and C remain as shown, while D is given as 2.899 ± 0.005.

(a) Determine the extreme variations of E that could ever result.

(b) Repeat part (a) from a statistical viewpoint.

Attachment:- Project Statistics In Manufacturing.rar