Reference no: EM132387200

FEDERATION UNIVERSITY AUSTRALIA

School of Science, Engineering and Information Technology

Mining Engineering Program

ENGIN2503 Surface Mining Operations and Equipment

Assignment: Design Project

Question 1. A new coal mining operation is to be worked employing surface mining using blasting to clear an overburden of Shale using 150mm holes and 11m benches. Dry rock conditions are anticipated and the decision is to use bulk ANFO with emulsion cartridges as a primer. The density of compacted ANFO = 0.85 g/cm3 and the PF is expected not less than 0.65 kg/m3. You are required to do the blast design to facilitate the production request of stripping 2,000,000 m3 overburden annually, including the followings,

(1) Drilling and blasting schedule and production;

(2) Blasthole drilling pattern;

(3) Details of blasthole parameters, e.g. burden and spacing, subdrill and inclination;

(4) Details of blast control techniques employed;

(5) Blast circuit / initiation pattern.

Please include a design drawing whenever appropriate for each of the design.

Question 2. Illustrate with suitable cross-section sketches showing ore and waste components, how overall stripping ration can be;

a. Constant

b. Increasing

c. Decreasing over the life of an open-pit mine.

Question 3. Two surface mines are considering the use of a conveyor in conjunction with their current fleet of trucks and shovels. The mines are;

i. a strip mine operation in which coal is transported out of the strip from a depth of 37m to a coal plant on surface, at a rate of 1.2 million tons per month.

ii. an open-pit operation in which coal and waste are transported from a depth of 300m to either a waste dump or a processing plant on surface, at a rate of 1.22 million tons per month (ore) at a stripping ratio of 3:1.

Give advice to the mines concerning the practicality and utility of using a conveyor to either replace or supplement the existing systems with proper justification.

Give advice to the mines as to what extra additional equipment they may need if they were to combine existing and new conveyor systems with proper justification.

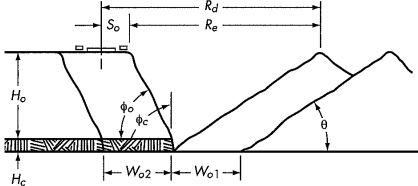

Question 4. A coal strip mining is designed to use dragline operation as illustrated below. The swell of the spoil is 1.25 to 1.30. You are required to design the effective radius Re and select a dragline that is suitable to the mine. Ho = 16 m, Hc = 4.5 m, pit width = 40 m, Φo = Φc = 70°, θ = 40°.

ENGIN2503: Rock Mechanics Applications

Project and Lab Work

Question 1

A discontinuity is found fully developed from the toe to the bench surface on a 15 m high slope, slope angle 65°. The discontinuity (frictional angle 32° and cohesion 20 kN/m2) is planar and its strike is parallel to the slope face with a dip 45°. Determine the factor of safety in case of a planar slope failure. Unit weight of the rock is 27 kN/m3. You are required to use RocPlane software to evaluate the stability of the slope. If the factor of safety is less than 1.3, then you need to design slope reinforcement system to raise the factor safety to 1.3.

Question 2

A series of shear tests were performed on a weak rock. Each test was carried out until the sample sheared, and the principal stresses for each test were:

|

S. No.

|

σ3 (KN/m2)

|

σ1 (KN/m2)

|

|

1

|

200

|

570

|

|

2

|

300

|

875

|

|

3

|

400

|

1162

|

Plot the Mohr's stress circle and hence determine the angle of internal friction and cohesion of the rock from Mohr's envelope. If the confining pressure was 600 KN/m2, extrapolate the failure stresses of the rock sample.

Question 3:

The following table shows data obtained from a single-stage triaxial compression test on a cylindrical rock sample, conducted with closed-loop servo-control, at a confining stress of 10.0 MPa, and at zero pore pressure.

|

Total Axial Load (KN)

|

Sample Height (mm)

|

Sample Diameter (mm)

|

|

0.00

|

100.84

|

50.20

|

|

19.89

|

100.80

|

50.20

|

|

39.60

|

100.77

|

50.20

|

|

63.40

|

100.74

|

50.20

|

|

88.67

|

100.71

|

50.21

|

|

116.18

|

100.68

|

50.21

|

|

144.68

|

100.65

|

50.22

|

|

162.38

|

100.63

|

50.22

|

|

185.23

|

100.58

|

50.24

|

|

190.62

|

100.56

|

50.25

|

|

191.99

|

100.54

|

50.25

|

|

180.22

|

100.52

|

50.26

|

|

137.56

|

100.49

|

50.26

|

|

115.79

|

100.46

|

50.27

|

|

101.93

|

100.43

|

50.28

|

|

97.97

|

100.40

|

50.28

|

|

96.98

|

100.37

|

50.28

|

Draw the complete stress-strain curve and determine values for the following:

1. Peak strength

2. Residual strength,

3. Tangent Young's modulus at 50% peak axial stress; and

4. Poisson's ratio at 50% peak axial stress.