Reference no: EM132539512

ENCH 403 Process Modeling and Simulation in Chemical Engineering - National University of Science and Technology

Aim - This coursework aims to develop student's ability to understand the Process Modeling and Simulation for Chemical Engineering systems.

Learning Outcome 1: Understand the concept of mathematical models and application of their relevance in chemical engineering problem.

Learning Outcome 2: Formulate the mathematical models for chemical engineering systems.

Learning Outcome 3: Understand the concept of simulation of a process and apply them to solve process engineering problem.

Part 1. A tank which has a diameter of 3 m which is used to store crude oil. The shape of the tank is spherical. A dip stick which is 4 m long would be wet with oil when immersed in the tank when it contains 2 m3 oil. Calculate height ‘h' to which a dipstick is wet with oil. The model equation is

h3 - 7 h2 + 1.347 = 0

Use secant method to find height ‘h'. Take initial approximations h0 = 0.5 and h1 = 1.

Part 2. Consider a system of three Continuous Stirred Tank Reactor connected in series. Product B is produced and reactant A is consumed in each of the three perfectly mixed reactors by a first-order reaction occurring in the liquid. Density is assumed to be constant throughout the system. With a neat diagram and suitable assumptions, formulate the mathematical model for this system with respect to constant hold up and variable hold up.

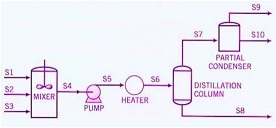

Part 3. Develop the model equations for the below acyclic flow sheeting using sequential modular approach.

Part 4. Assume that you are going to build up a model for a system where unit operation and unit processes are carried out. Explain the various steps involved in the process of model building for the system you have chosen.

Part 5. Explore the various applications of modeling and simulation in chemical and process industries and enumerate their pros and cons with respect to chemical engineering systems.

Attachment:- Process Modeling and Simulation.rar