Reference no: EM132080156 , Length: 15 pages approx

1. Following on from the first TMA in this module, produce a design report for ONE design of the product based on ONE of the scenarios covered on the following pages. The report should contain, where appropriate:

- Title page

- Acknowledgements

- Summary

- Contents

- Introduction

- Basic Product Design Specification

- Design Parameters

- Simple Description of chosen Design

- Design Evaluation

- Detailed drawings of the design, including dimensions, such that its constructional features can be seen*

- Conclusions

- References

- Appendices.

*Drawings should be submitted as complete engineering drawings done using CAD (or other suitable software). If the maximum size of printing is A4 then several sheets, each showing a different view of the design, will probably be needed to show sufficient detail for the design to be constructed. In this case, all views should be clearly labelled and all sheets numbered. Only computer-produced drawings will be marked: it is not acceptable to submit hand-drawn work. Please submit a hard copy of the drawing as part of the report (in pdf) along with the computer files of the drawings.

Note: you may have to invent information to make the Report complete.

SCENARIOS

Either

(a) Bicycle Rack

When a full design specification was produced and the weighted objective procedure carried out, it was found that a tow bar mounted rack was the best solution. This would bolt to the tow bar once the tow ball has been removed.

The dimensions of the tow bar bracket are as shown in FIGURE 1. The 330 mm dimension refers to the distance from the ground to the bottom of the bracket. In order to avoid the bikes fouling the car, it should be assumed that no part of either bike should protrude beyond the face of the tow bar bracket.

FIG. 1

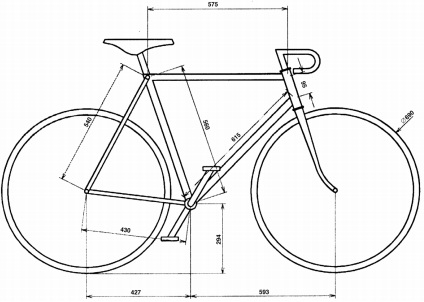

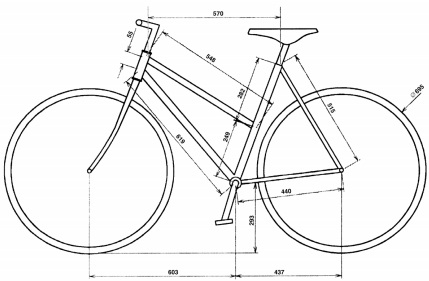

The two bikes to be carried have the dimensions shown in FIGURES 2 and 3. The width of the handlebars of the man's bike (FIGURE 2) is 420 mm whilst that of the lady's bike (FIGURE 3) is 630 mm. The width across the pedals is 360 mm in both cases.

Your good friend Fred has offered to help build the bike rack and he has access to the following materials and equipment:

Square section steel tubing 25 mm × 25 mm, 2 mm thick Steel plate 8 mm thick

Steel strips 25 mm wide by 6mm thick Brazing and welding gear

A powered hacksaw A Pillar drill.

Design a suitable rack that can be made using Fred's materials and equipment. It is not necessary to worry about stresses, the materials are capable of exceeding the strength requirements of any design, and the rack should be designed to ‘look right'.

As part of the Design Report, you should produce:

(i) An arrangement drawing showing the outline of the bikes on the rack. This does not need to be very detailed or show any dimensions but should clearly demonstrate that the rack will enable the two bikes to be carried without fouling the car or the ground.

(ii) A detailed engineering drawing of the rack only, showing front and side views with all dimensions required for manufacture shown on them.

FIG. 2

Fig.3

OR

(b) Front Panel of Circuit Trainer

An analogue/digital circuit trainer is required for open learning students to use to build circuits as part of their electrical/electronic practical work.

The circuits that are to be built can consist of up to five integrated circuits and their associated discrete components.

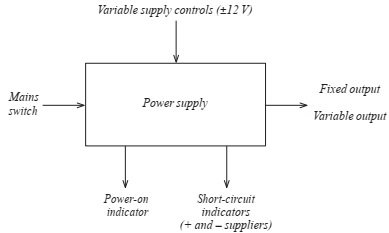

FIGURES 4, 5 and 6 each show a block diagram for each system of the intended design:

(i) Power supply consisting of

- 240 V supply input

- Power ‘on' indicator

- +5 V output

- +12 V output

- -12 V output

- 0 to +12 V variable output

- 0 to -12 V variable output

- Output short-circuit indicators for ‘+' and ‘-' supplies.

FIG. 4

(ii) Function Generator capable of

- generating sinusoidal, triangular and square waveforms

- variable amplitude

- variable frequency

- frequencies in the ranges 0 to 100 Hz, 100 Hz to10 kHz and 10 kHz to 1 MHz.

FIG. 5

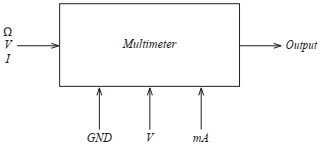

(iii) Multimeter capable of measuring

- resistance

- voltage

- current.

FIG. 6

You will be required to draw a plan view of the front panel to show the mounting of the various controls, etc. A photograph of an example of an existing circuit trainer is given in FIGURE 7.

FIG. 7