Reference no: EM13708244

(a) Develop your knowledge of key principles relating to wastewater system design

(b) to develop technical competence in problem formulation and solution in this discipline area, and

(c) to improve your teamwork and technical communication skills, with particular emphasis on presentation and setting out solutions.)

Part A will be the estimation wastewater flows and Part B will be the design of trickling filter-activated sludge system.

PART A: Estimation of Wastewater Flows

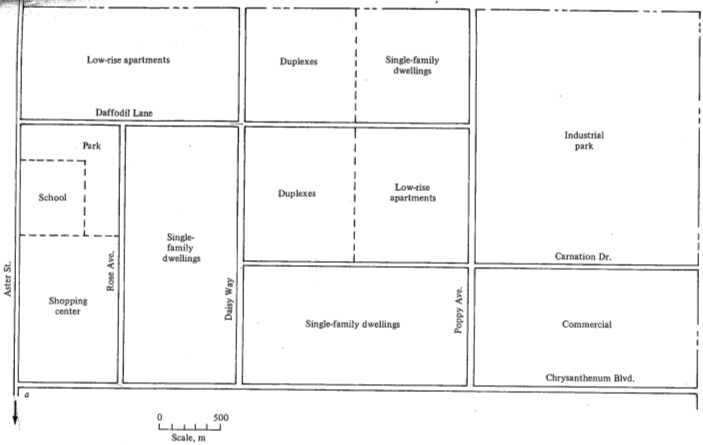

Data on the expected saturation population densities and wastewater flows for the various types of housing in the New Park Development (Figure 1) were derived from the actual records of similar nearby developments and are given in the table (Table 1). The flowrate allowances for the commercial (including the shopping area) and industrial wastewater were estimated to be 25 and 35 m3/(ha.day) respectively.

Figure 1: Classification of land use

On the basis of actual flow records of similar activities, the average peak factors are 2 for the commercial flows and 2.5 for the industrial flows. The planned school within the New Park Development is to serve 2500 students at ultimate capacity. The average flow is 80 L/(student. day), and the peak factor for the school is 4.0.

Assume the average park attendance is 300 persons/day and the flow is 70 L/person.d. The peaking factor for the park is 4.0. Estimate the expected average and peak wastewater flows from the New Park development at the end of full development.

PART B: Designing of Trickling Filter (TF) /Activated Sludge (AS) Systems

A TF/AS process is used after primary clarification and the primary effluent wastewater characteristics are given below (Table 2). For the following design parameters, compare the effect of designing the plastic tower trickling filter for 40 percent versus 75 percent BOD removal:

1. Trickling filter diameter (m) and hydraulic application rate (L/m2.s)

2. Oxygen required in the activated -sludge aeration tank (kg/d)

3. The amount of solids wastes per day (kg/d)

4. The volume (m3) and hydraulic retention time (h) of the aeration tank.

Use the following assumptions for the trickling filter and activated sludge design.

Trickling Filter:

Plastic packing treatability coefficient, k20 = 0.18 (L/s)0.5/m2

Packing depth = 6.1 m

Number of towers = 2

50 percent of theoretical effluent BOD is soluble

Activates sludge:

SRT = 5.0 day (no nitrification)

MLSS = 3000 mg/L

Biomass yield , Y = 0.6 g VSS/g BOD removed

Endogenous decay, kd = 0.12 g VSS/g VSS.d

UBOD/BOD = 1.6

|

What is the enthalpy of the water in units

: 5.5 kg of superheated water vapor is at 200°C and 1.4 MPa. It is cooled at constant volume to 150°C. What is the enthalpy of the water in units of kJ? (Please note it is asking for the final enthalpy, as well as in units of KJ, not KJ/kg)

|

|

Temperature measurement device is calibrated to produce

: A temperature measurement device is calibrated to produce 4-20 mA for a temperature operation range of 0-100 degree C. Sketch the input-output characteristic chart of the device, assuming linear input/output relationship.

|

|

An enclosure contains an array of circuit boards

: An enclosure contains an array of circuit boards, 15 cm high and 20 cm long. The clearance between the tips of the components on the PCB and the back surface of the adjacent PCB is 0.3 cm. Each circuit board contains 75 square chips on one side, each..

|

|

Determine amount of heat removed during the cooling process

: A rigid container of 0.1 m3 and negligible heat capacity contains steam at 500 kPa and 400C. If the container is cooled, determine the pressure and temperature at which steam starts to condense. Determine also the amount of heat removed during the co..

|

|

Develop technical competence in problem formulation

: Develop your knowledge of key principles relating to wastewater system design - Develop technical competence in problem formulation and solution in this discipline area.

|

|

Determine the mass flow rate of air through the compressor

: Air enters the compressor of a gas-turbine plant at ambient conditions of 100 kPa and 32 °C with a low velocity and exits at 1 MPa and 367 °C with a velocity of 6 x 10^3 m/min. The compressor is cooled at a rate of 1800 kJ/min, and the power input to..

|

|

Maximum inner diameter for the shaft for a yield strength

: A shaft with a 2-inch outer diameter must deliver 5000 ft-lbs of torque. The shaft must be hollow and must simultaneously carry hydraulic fluid at an internal pressure of 30,000 psi. Assuming the shaft is closed-ended, and using the von Mises yield c..

|

|

Business to succeed in today''s business environment

: 750 words discussion question. How important is it for sustainable business practices to take hold in order for a business to succeed in today's business environment?

|

|

An individual, owns a proprietorship called green

: 1. Roger, an individual, owns a proprietorship called Green Thing. For the year 2014, Roger has the following items:-Business income-$200,000.

|