Reference no: EM131871584

Topic: Chemical Process HAZOP & Risk Analysis Questions -

Q1. The hydrolysis of acetic anhydride is being studied in a laboratory scale continuously stirred tank reactor (CSTR). In this reaction acetic anhydride [(CH3C0)20] reacts with water to produce acetic acid (CH3COOH).

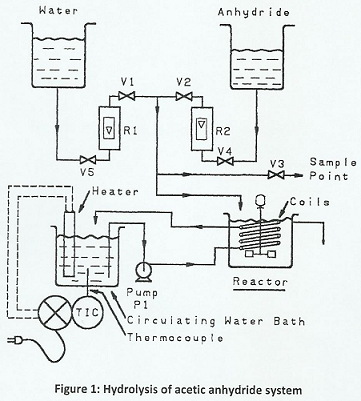

The initial experimental design is shown in Figure 1. Water and acetic anhydride are gravity fed from reservoirs and through a set of rotameters. The water is mixed with the acetic anhydride just before it enters the reactor. Water is also circulated by a centrifugal pump from the temperature bath through coils in the reactor vessel. This maintains the reactor temperature at a fixed value. A temperature controller in the water bath maintains the temperature to within 1oF of the desired temperature.

Samples are withdrawn from the point shown and titrated manually in a hood.

a) Develop a safety checklist for use before operation of this system. (At least 10 items).

b) What safety equipment must be available? (At least 8 items).

Q2. Feed section of proposed olefin dimerization is shown in Figure 2 (attached). A C6 hydrocarbon stream (averaging 25 m3/hour) from the reflux drum of an atmospheric distillation column is run down on exit level control via the reflux pumps into the 250 m3, nitrogen-blanketed, intermediate storage tank (1ST). This stream normally contains about 50 mole % mixed C6 alkenes and about 50 mole % mixed C6 paraffinic hydrocarbons together with small amount of suspended water (typically 1% v/v). The bulk of the water separates out in this tank and is drained off manually at 4 hours intervals.

The IST serves as a buffer and temporary storage for the material before the C6 material is pumped by the J1 centrifugal pump to the gasoline blending unit and reactor feed /settling tank (RFST). The IST normally operates at 20 C and 5 psig on split range pressure control from the 10 psig nitrogen supply. The tank is protected by a pressure relief valve (RV).

a) For all applicable process parameters, perform a HAZOP study on-the:

i. Section of the line from the IST to the reactor feed/settling tank.

ii. Reactor feed /settling tank.

b) What specific recommendations can you make to improve the safety of this system? Be specific to the given system.

Attachment:- Assignment File.rar