Reference no: EM131055204

Problem #: Casting

Solve the following manufacturing optimization problem using the computer code that you previously created to simulate solidification during casting processes.

The material is once again the well-known polymer known as PEEK (polyetheretherketone). The properties of this material are as follows:

k = 0.251 W/mK, ρ = 1262 kg/m3, Cps = Cpl = 1339 J/kgK

Ts = 330oc = 603K, Tl = 345oC = 618 K

hs = CpsTs = 807,417 J/kg, hl = CplTl = 827,502 J/kg

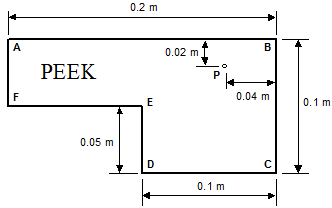

Assume the two-dimensional configuration shown below. Also assume that Tinitial = 650 K everywhere in the interior of the casting (i.e. the pouring temperature). At time t= 0 the wall temperature is to be set to Twall = 425 K along the mold wall region AFED. Along this portion of the mold wall you have no control over this fixed mold wall temperature.

To make your manufacturing process adjustable, your mold has been designed to have the ability to adjust the three mold wall temperatures applied along boundary regions AB, BC, and CD respectively. The temperatures along these three wall segments can be set to any levels that you desire, but they have to remain constant throughout the product casting cycle.

Using an optimization methodology that you design, determine the wall temperatures to be applied along AB, BC, and CD so that 1) the last point to solidify in the casting is point P, and 2) the time for complete solidification of the product is as fast as possible.

Optimize this solidification problem numerically, and hand in the following:

- A description of the optimization methodology that you selected, and a listing of all of the wall temperature boundary condition sets that you simulated during the optimization process.

- A clear statement of the FINAL OPTIMAL THREE WALL TEMPERATURES that you determined.

- For the optimal conditions above, a plot of Tp versus time

- For the optimal conditions above, the total solidification time and final point of solidification within the product.

- For the optimal conditions above, a plot showing the temporal progression of solidus interface fronts during the casting process.

Attachment:- code.rar

|

What is meant by off balance sheet liabilities in article

: What are the main differences between IAS 17 (AASB 117) and the new IFRS 16 (AASB 16) from the lessee perspective? What is meant by ‘off balance sheet liabilities' in the article

|

|

Seven domains of it within the organization

: Identify vulnerabilities in the seven domains of IT within the organization. This is similar to #2. This is not necessarily based solely on the scenario because specific vulnerabilities are not listed; just list vulnerabilities that may exist, i..

|

|

Fund assuming that only the interest income is distributed

: George Jefferson established a trust fund that provides $178,500 in scholarships each year for worthy students. The trust fund earns a 5 percent rate of return. How much money did Mr. Jefferson contribute to the fund assuming that only the interest i..

|

|

Possibility of small scale profitability entry in small

: Viton's 1981 study of urban transit costs found that urban transit firms operating in small cities (where fewer than one million vehicle-miles are produced annually) operate under increasing returns to scale, Assuming that fares are set at marginal c..

|

|

Determine the wall temperatures

: Determine the wall temperatures to be applied along AB, BC, and CD so that 1) the last point to solidify in the casting is point P, and 2) the time for complete solidification of the product is as fast as possible.

|

|

Renfro rentals has issued bonds

: Renfro Rentals has issued bonds that have a 12% coupon rate, payable semiannually. The bonds mature in 9 years, have a face value of $1,000, and a yield to maturity of 9.5%. What is the price of the bonds?

|

|

Conduct a risk analysis of a building

: The aim of this research is to conduct a risk analysis of a building retrofit project following life cycle approach, from investor perspective and focus on investment risks.

|

|

Project manager for new management accounting system

: You are the project manager for a new management accounting system that will provide monthly profit and loss accounts to a chain of 30 computer dealerships, each of which is franchised to its local owner/manager.

|

|

Temporary project that will generate the cash inflows

: The firm will also be required to spend $10,000 to close down the project at the end of the three years. If the cost of capital is 10 percent, should the investment be undertaken?

|