Reference no: EM131736

Your team has been charged with creating the pumping and piping system to supply cool water to the condenser, E-310, for the newly installed distillation column T-304 running at 120 psi. The condenser will be supplied with once-through cooling water from a nearby lake, T=70°F. The condenser duty, Q, is calculated to be 0.5 MMBtu/hr. You must design a pumping and piping system to provide adequate cooling to the condenser. Below is a schematic of the relevant location of process equipment.

The water will be pumped out of a lake by a pump you will design. You must determine the location the pump will be placed. The piping system you develop may be placed along preexisting pipe racks as described in the above graphic. The piping will continue to E-310 which is located at 85 ft above elevation (ground level), at the top of T-304. The water exits the condenser and is returned to the lake.

The return temperature of the water plays a critical role in determining the size of pumping and piping equipment. This is a design variable for you to decide.

Equation:

Q = F.Cp.ρ.ΔT

The cooling water will experience an estimated 5 psi pressure drop over the condenser and be returned to an underground common return which empties into the lake akin to a sewer system in the plant.

Where Q is the heat duty on the condenser and F is the volumetric flow rate, Cp is the heat capacity, is the density, and is the temperature differential of the lake water through the condenser.

The diameter of the pipe also plays a critical role in determining power needed by a pump to move liquid from one location to another. A larger diameter decreases the required pumping power, but at the cost of higher initial investment. Your job is to develop a pumping and piping system for E-310 with this optimization in mind.

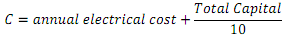

The project life will be 10 years. Capital investment will be paid for over the project life in equal payments. Your goal is to minimize total yearly cost as defined by: