Reference no: EM13199974

Question 1

You are the operations manager of a firm that uses the continuous-review inventory control system. Suppose the firm operates 52 weeks a year, 365 days, and has the following characteristics for its primary item:

Demand = 25,000 units/year

Ordering cost = $30/order

Holding cost = $8/unit/year

Lead time = 2 weeks

Standard deviation in weekly demand = 100 units

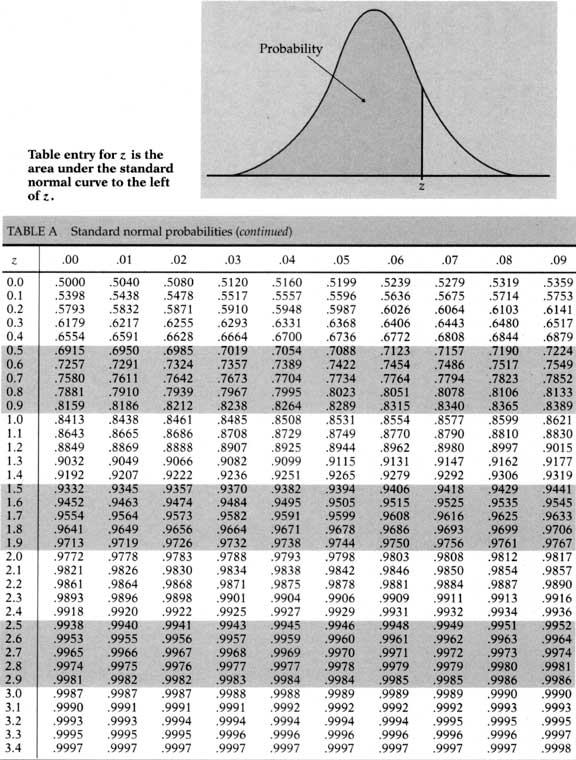

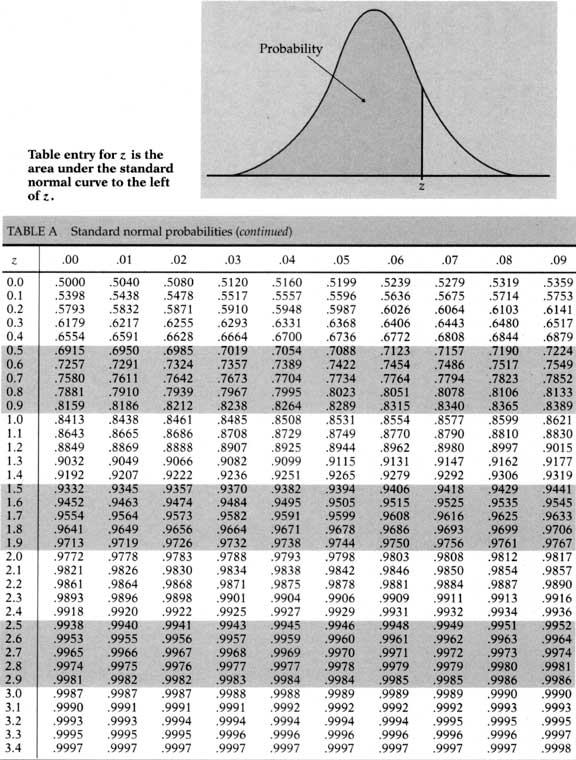

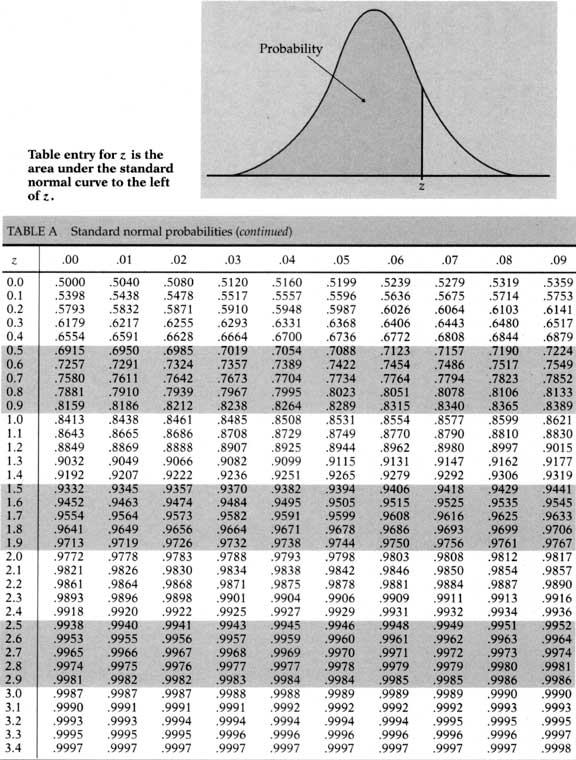

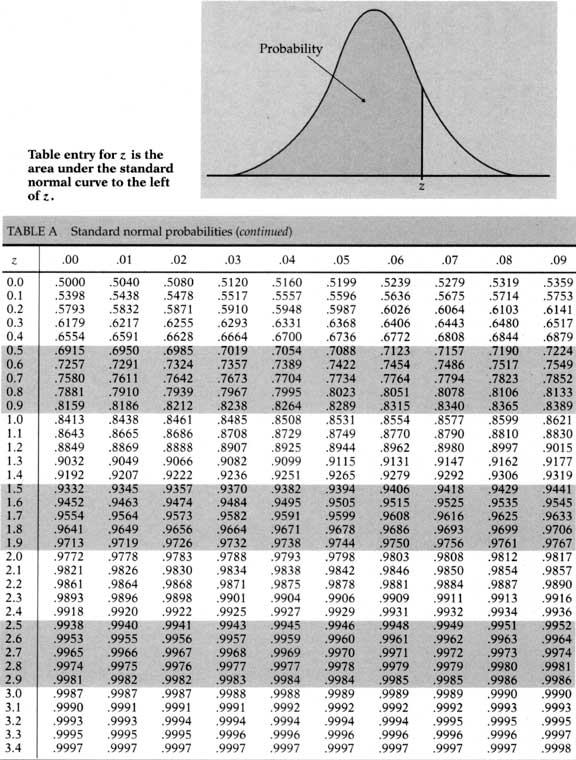

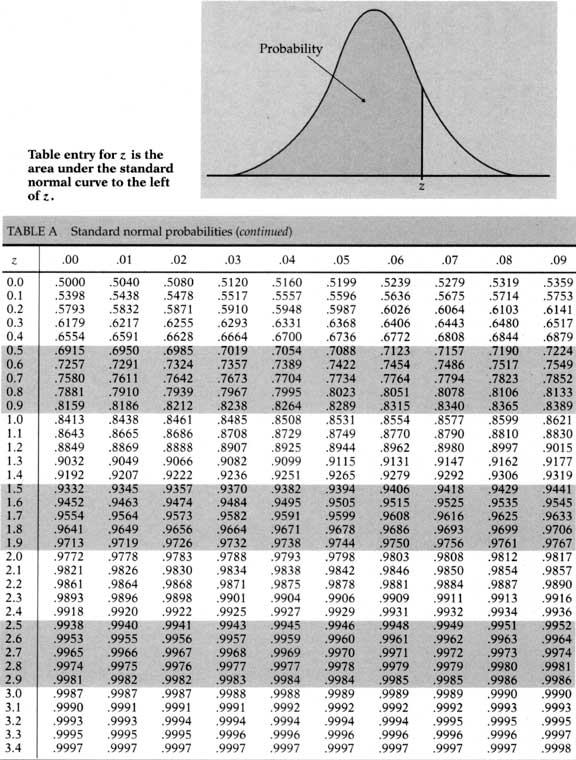

A normal distribution table is shown below.

Use the information in Table. What is the economic order quantity for this item?

Fewer than 400 units

Between 400 and 450 units

Between 450 and 500 units

Greater than 500 units

Question 2

You are the operations manager of a firm that uses the continuous-review inventory control system. Suppose the firm operates 52 weeks a year, 365 days, and has the following characteristics for its primary item:

Demand = 25,000 units/year

Ordering cost = $30/order

Holding cost = $8/unit/year

Lead time = 2 weeks

Standard deviation in weekly demand = 100 units

A normal distribution table is shown below.

Use the information in Table 12.4. What is the length of their order cycle if they order the economic order quantity each time?

Less than four days

Between four and five days

Between five and six days

Greater than six days

Question 3

You are the operations manager of a firm that uses the continuous-review inventory control system. Suppose the firm operates 52 weeks a year, 365 days, and has the following characteristics for its primary item:

Demand = 25,000 units/year

Ordering cost = $30/order

Holding cost = $8/unit/year

Lead time = 2 weeks

Standard deviation in weekly demand = 100 units

A normal distribution table is shown below.

Use the information in Table. What is the reorder point for this item if they use a 95% service level?

1,046 units

170 units

1,194 units

68 units

Question 4

You are the operations manager of a firm that uses the continuous-review inventory control system. Suppose the firm operates 52 weeks a year, 365 days, and has the following characteristics for its primary item:

Demand = 25,000 units/year

Ordering cost = $30/order

Holding cost = $8/unit/year

Lead time = 2 weeks

Standard deviation in weekly demand = 100 units

A normal distribution table is shown below.

Use the information in Table. If this form uses an EOQ model for purchase decisions, which change would result in the biggest increase in order quantity over the amount required by the original data?

The cost of ordering rises to $50 per order.

The holding cost drops to $5 per unit per year.

The annual demand soars to 30,000 units per year.

The lead-time increases to three months.

Question 5

Peterson Enterprises uses a continuous review inventory control system. The firm operates 50 weeks per year and has the following characteristics for an item:

Demand = 50,000

Ordering cost $35/order

Holding cost = $2/unit/year

Lead time = 3 weeks

Standard deviation in weekly demand = 125 units

A normal distribution table is shown below.

Use the information in Table. What is the EOQ for this item?

Fewer than 1,100 units

Between 1,100 and 1,200 units

Between 1,200 and 1,300 units

More than 1,300 units

Question 6

1. Cynthia Korinsky, manager of a large medical supply house that operates 50 weeks per year and five days per week, has decided to implement a periodic review system for all class A items. One such item has the following characteristics:

Demand = 10,000 units per year (or 40 units per workday)

Order cost = $50 per order

Holding cost = $5 per unit per year

If Korinsky wishes to minimize total cost (thereby approximating the EOQ), what should be P, the number of workdays between orders?

Fewer than or equal to 10 days

Greater than 10 days but fewer than or equal to 12 days

Greater than 12 days but fewer than or equal to 14 days

Greater than 14 days

Question 7

Demand = 5,200 units/year

Standard deviation of weekly demand = 11 units

Ordering costs = $45/order

Holding costs = $2/unit/year

Cycle-service level = 90% (z for 90% = 1.28)

Lead time = 3 weeks

Number of weeks per year = 52 weeks

Use the information in Table. The firm decided to change to the periodic review system to control the item's inventory. For the most recent review, an inventory clerk checked the inventory of this item and found 500 units. There were no scheduled receipts at the time. How many units should be ordered? (HINT: Use the EOQ model to derive P, the time between reviews.)

0 units

Between 1 and 300 units

Between 301 and 600 units

Above 600 units

1 points

Question 8

Demand = 5,200 units/year

Standard deviation of weekly demand = 110 units

Ordering costs = $45/order

Holding costs = $0.50/unit/year

Cycle-service level = 90%

Lead time = 2 weeks

Number of weeks per year = 52 weeks

A normal distribution table is shown below.

Use the information in Table 12.7. A firm uses the periodic review system to control the item depicted above. It reviews the item's status every three weeks (P = 3). At the most recent inventory review, an inventory clerk found 1,500 units. There were no scheduled receipts and no backorders. How many units should be ordered? (Hint: You must calculate T before answering this question.)

0 units

Between 1 and 3,750 units

Between 3,751 and 4,000 units

Greater than 4,000 units

Question 9

Demand = 5,200 units/year

Standard deviation of weekly demand = 110 units

Ordering costs = $45/order

Holding costs = $0.50/unit/year

Cycle-service level = 90% (z for 90% = 1.28)

Lead time = 2 weeks

1. Number of weeks per year = 52 weeks

A normal distribution table is shown below.

Use the information in Table. What is the EOQ for this item?

Between 1 and 1,500 units

Between 1,501 and 3,000 units

Between 3,001 and 4,500 units

Greater than 4,500 units

Question 10

1. Under a cycle counting system for checking inventory accuracy:

the length of the time between orders determines which items are counted most frequently.

the A items are counted most frequently.

the items with the highest holding cost are counted most frequently.

the items that have been withdrawn last are counted most frequently.