Reference no: EM132386991

Question 1. Choose one product and construct a materials and energy flow diagram, with minimal detail in the pre-manufacturing and manufacturing stages and enhanced detail in the product delivery and use stage. Suggest appropriate actions by the design engineer.

Question 2. Compare the use of virgin paper and recycled paper. Compare from an environmental point of view the use of recycled paper and the use of paper obtained from paper pulp. The recycled paper has been obtained from paper wastes transported in 16-t trucks from a distance of 1000 km. The total emissions of carbon dioxide, CO2, and the generated solids in kg of them are used as comparison parameters. It is desirable to compare the derived effects of the following two scenarios:

• purchasing a 400-g pack of new writing paper at the corner stationery shop

• driving to buy a similar pack of recycled paper at an establishment 1 km away.

Only the ELs due to raw materials and transportation are considered. Use the following environmental loads:

|

EL/kg of recycled EL/kg of pulp

EL paper paper EL/km (car)

|

EL/tkm f 16-t truck)

|

|

kgCO2 1.03 1.61 2.16 x 10-1

kg solids 7.06 x 10-2 1.73 x 10-1 7.50 x 10-6

|

3.46 x 10-17.19 x 10-2

|

tkm is equivalent to a mass of 1 t (1000 kg) transported 1 km.

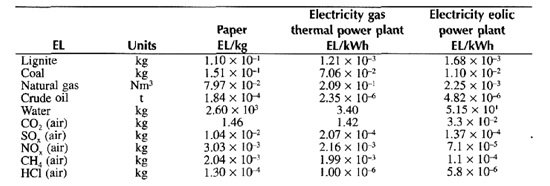

Question 3. Compare the use of paper towels and an air dryerto drying the hands. Compare environmentally the use of paper towels for drying hands and the use of a hand-dryer supplied with electricity from a gas thermal power plant or from an eolic power plant. The considered comparison parameters are the emissions of carbon dioxide, CO2, and sulfur dioxide, SO2.

Suppose that the weight of a paper towel is 7 g and that the electric hand-dryer is 2000 W and works for 30 s. With these data, determine the best way, from an environmental point of view, to dry the hands. The ELs related to the paper and the use of electricity are assumed to be the following:

Electricity consumption: Ec(kWh); Ec = (2000 (J/s)/1000)(30/3600) = 1.67 X 10-2 kWh.

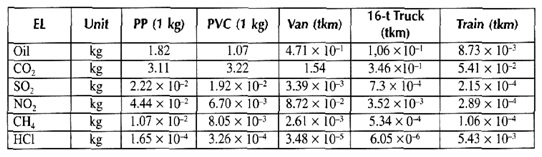

Question 4. Compare the use of two different plastics: PP and PVC. A company endeavors to compare the environmental impact due to the industrial use of two polymers: polypropylene (PP) and polyvinyl chloride (PVC) as raw material for manufacturing piping. It considers it necessary to take into account two variables: the raw material and its transport. Two alternatives are supposed:

a) Buying PP piping from a distributor who receives the product by train from a factory 1000 km away and uses a van to deliver the product to a consumer who is 200 km from the distributor

b) Buying PVC tubes from a distributor who acquires the product by a 16-t truck from a factory 700 km away and uses a van to deliver the product to a consumer who is 50 km from the distributor

To compare the environmental behavior of each product, the company makes use of three parameters: kilograms of consumed oil, GWP measured as kilograms of equivalent CO2, and acidification (acid potential, AP) measured as kilograms of equivalent SO2.

Determine for each alternative the value of these parameters related to environmental impact caused by the use of 1 kg of polymer and determine which of these kinds of plastics would be better used from an environmental point of view. The necessary ELs and impact factor data are given in the following table.

tkm equivalent to a mass of 1 t (1000 kg) transported 1 km.

Environmental impact factors:

| GWP |

AP |

| Component |

Factor |

Component |

Factor |

| CO2 |

1 |

SOx |

1 |

| CH4 |

62 |

NOx |

0.7 |

|

|

HCL |

0.88 |

Question 5. Select a product of moderate complexity, such as a toaster, a desktop telephone, or an overhead projector.

1) Conduct an SLCA on the product.

2) Prepare a report that summarizes your findings, comment on where it was difficult to assign ratings because of lack of information, and propose design changes that would improve the environmental responsibility of product.

Question 6. Choose ONE case from Problems 2, 3, and 4. Use Gabi 4 to develop a plan of the product system, including essential processes and flows, related to the delivery and use phases, and to conduct a balance assessment.