Reference no: EM132255550 , Length: word count:2500

Industrial Systems Assignment - GRACO

Learning Outcomes -

1. Describe the main elements of an electronically controlled industrial system.

2. Identify and specify the interface requirements between electronic, electrical and mechanical transducers and controllers.

3. Apply practical and computer-based methods to design and test a measurement system.

4. Apply appropriate analytical techniques to predict the performance of a given system.

Assignment Brief and Guidance -

Scenario: You are working as an Industrial Technician in Graco, which is a highly reputed engineering industry, dealing with the design, development, and manufacture of numerous industrial applications. Your job involves utilizing the most appropriate technology for each application, to ensure the most efficient monitoring and control of variables such as pressure, temperature and speed.

By applying your knowledge of Industrial Systems, your first task would be to write a report on the main elements of an electronically controlled industrial system. Please refer Task 1 for this.

You would also have to identify and specify the interface requirements between electronic, electrical and mechanical transducers and controllers, by justifying the choice of transducers and controllers for the given task, and critically investigating the behavior of a given control system. For this, you would also need to predict the best solution amongst different variety of transducers used for a given problem.

Your job would also involve doing practical and computer-based work to design and test a measurement system. For a given system, you would need to apply analytical techniques to predict the performance of that system.

You need to do the following tasks. All of the above duties.

Task 1 -

Part 1 -

1. Compare open-loop and closed-loop control systems. Give an example of both systems.

2. State the basic functions of each of the following as part of a process-control system:

3. Calculate which of the following motors gives the greater load acceleration:

- Motor A - has a maximum torque of 0.15 N-m and an inertia of 2.5kg-m2.

- Motor B - has a maximum torque of 0.25 N-m and an inertia of 5kg-m2 Part 2.

Part 2 -

4. Determine the gear ratio necessary to obtain greatest load acceleration, and then calculate the maximum load acceleration, if the load inertia is 450kg-m2 , using the motor with the greater load acceleration.

5. Use diagrams to help describe how it is possible to control the speed of an AC servo-motor using a closed-loop speed control system. Explain how the error signal is formed and discuss what 'fault' conditions could cause the speed to drop abnormally.

Task 2 -

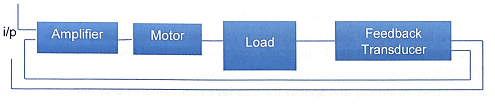

Part 1 - For the speed control system shown in the figure below, the feedback transducer has a transfer function of 50mV per r/min and the transfer function for the motor/load is 100 r/min per volt. The reference signal applied to the system is 100 V. Given that the allowable speed error is 40 r/ min, determine the amplifier gain (transfer function)

Part 2 - For the system in the above question the reference voltage is reduced to 80V. Determine the corresponding reference speed.

For the system in the above question, the load speed is adjusted to 1900 r/min. Determine the corresponding reference voltage. Critically investigate the behaviour of the control system to compare the above 3 approaches.

Task 3 -

Part 1 - For your laboratory work, you have to test a measurement system, like digital voltmeter, digital ammeters, etc. or any other measurement system available in your laboratory. The approach for this test would be practical and computer based.

Part 2 - Explain the procedure for this and talk about accuracy, resolution, tolerances, stability, sensitivity and response time for that measuring system. Critically evaluate the performance of an ideal measurement system compared to a real circuit.

Task 4 -

Part 1 - Write down the advantages and disadvantages of increase use of wireless and remote control in the GRACO Industry.

Part 2 - Analyse appropriate analytical techniques used in your Industry (GRACO) and justify your recommendations to improve the performance.