Reference no: EM13246345

Design a processing route to manufacture a continuous-fibre reinforced polymer matrix material that meets a specified set of mechanical property requirements. Initially each team will need to use CES material selection software (level 3) to identify appropriate fibre and matrix types and then use appropriate literature to design a fully-justified manufacturing process route to make a flat panel from that material. The flat panel should have the dimensions 140 mm x 12.5 mm (tolerance of 0.5 mm) and should have a thickness between 4 mm and 5mm. The fibres should be uni-directional and oriented in the longitudinal (140 mm) direction.

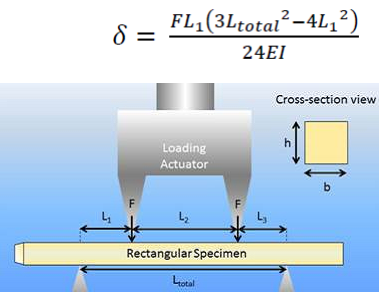

While the panel will not be manufactured, the processing route should be designed to ensure that the porosity level in the panel is less than 2% and the panel should not deflect more than 1 mm when the load, F=0.5kN (see formula and diagram below) under four-point bend loading when supported over a 90 mm span (Ltotal). While the panel MUST meet the minimum loading properties, it is advantageous to make your composite as cheap as possible.

Project proposal requirements

While each group will design the material and processing route together, each individual team member will submit their OWN report. Individual reports should be 2000 words and include:

• Calculations that show the material composition (fibre and matrix type and volume fractions) will meet the property specifications, and a justification of why this material composition is the cheapest option

• A clear and detailed flow-chart highlighting each step of the proposed process route

• A clear and detailed justification of the conditions/parameters required for each step of the process using both literature references and fundamental theory

• Evidence of the individual student's contribution to the project proposal

• Individual reflection - this should be an honest individual reflection on how the team interacted and performed (including any negative aspects that need to be fixed for the second project, or any positive aspects need to be reinforced) as well as an assessment on what parts of the proposal you were least confident in and why you are unsure on those aspects (it is often necessary go with the best information available, even when you know it is not perfect - it is also important to recognise when you are doing this so that backup plans can be in place). Note - this reflection should not include other individual team member's names.

Team members may share raw information sources (such as journal articles); however, reports must be written individually.

Each team will also have a Cloud Deakin group site that they are required to use for the project. ALL information found should be uploaded to the site, including team meeting minutes, details of websites, journal articles or textbook information as they are found, as well as questions or problems encountered by the team. It is up to each individual in the team to PROVE their contribution to the project.

|

Explain the expected boiling point of a solution of sodium

: What is the expected boiling point of a solution prepared by dissolving 5.83 g of sodium iodide (NaI) in 59.2 g of water (H20)? For water, Tb = 100.00 degrees Celsius and Kb = 0.512 degrees Celsius m-1. The answer is 100.675. Please show a step by..

|

|

What is the total number of turns of the solenoid

: The strength of the magnetic field within a solenoid is B = 3.4 × 10-2 T, single loop is placed in the solenoid parallel to the plane of each loop in the solenoid, What is the total number of turns of the solenoid

|

|

Analyze the characteristics of all market structure

: Different market structures are prevailing in ourdifferent sectors like agriculture, power supply, transport industry, cement industry,restaurants, etc. Analyze and compare the characteristics of all marketstructure with respect to the given secto..

|

|

Explain what is the equilibrium concentration of nh4

: 15.0 mL of 0.50 M NaOH is added to a 100.-mL sample of 0.376 M NH3 (Kb for NH3 = 1.8 x 10^-5. What is the equilibrium concentration of NH4^+ ions? The answer is 9.0 x 10^-5 M.

|

|

Calculations that show the material composition

: Calculations that show the material composition (fibre and matrix type and volume fractions) will meet the property specifications, and a justification of why this material composition is the cheapest option

|

|

Analyze the top and explain the advantages of top

: Critics felt that TISCO might face problems due to the decrease in demand for steel in the global and local markets and increasing competition from cheap imports, and anti-dumping duties imposed on the domestic steel manufacturers by the US.

|

|

Explain the mixture is ignited with a spark

: A mixture of 6.0 mol of H2(g) and 3.0 mol of O2(g) is placed in a sealed evacuated container made of a perfect insulating material at 26 Celcius. The mixture is ignited with a spark and it reacts to form liquid water. Find the temperature of the w..

|

|

Find the power factor for given circuit

: An ac generator with a frequency of 1.44kHz and an rms voltage of 21.2V is connected in series with a 1.90 kiloohms resistor, What is the power factor for this circuit

|

|

Explain what minimum mass of succimer is needed to bind

: What minimum mass of succimer in milligrams is needed to bind all of the lead in a patient's bloodstream. Assume that patient blood lead levels are 0.530 mg/L , that total blood volume is 5.0 L , and that 1 mol of succimer binds 1 mol of lead.

|