Reference no: EM133006754

Dimensional Analysis & Hydraulic Machines

Learning Outcome 1: Personal & Transferable Skills

1 Demonstrate numerical skills in the calculation of static and dynamic fluid systems.

Research, Knowledge & Cognitive Skills

2 Describe and explain the principles and application of hydraulic machines.

3 Analyse static and fluid flow systems.

Professional Skills

4 Apply the theory of viscosity in fluids to engineering situations.

Question 1 A horizontal pipe is filled with liquid. When the liquid is stationary, its head H metres depends on the pressure p of the liquid, its density ρ and gravitational acceleration g. Determine the nature of the relationship of these variables.

Question 2 (a) Water (density 1000 kg m-3) is maintained at a gauge pressure of 4.5 MPa in a horizontal pipe of diameter 120 mm. It is passed through a nozzle of diameter 16 mm which discharges a horizontal jet into the atmosphere. If the frictional losses reduce the theoretical discharge velocity by 7% in this process, calculate the actual velocity of the jet and its flowrate in kgs-1.

(b) This jet strikes an upward curved vane moving at 20 ms-1 in a horizontal direction away from the jet, which deflects the water through an angle of 115º. The impact is shockless. Calculate:

(i) the magnitude and direction of the velocity of the fluid leaving the vane;

(ii) the thrust on the vane in a horizontal direction;

(iii) the thrust on the vane in a vertical direction;

(iv) the power generated by the impact in the horizontal direction.

Question 3 (a) Distinguish, with the aid of simple sketches where appropriate, between the construction, operation and applications of the Pelton wheel, Francis turbine and Kaplan turbine.

(b) In a Francis turbine, the supply head H is 25 m of water (density 1000 kgm-3). The discharge rate to atmosphere is 700 kgs-1. The external radius of the runner R1 is 0.48 m and the internal radius R2 is

0.22 m. The runner blades are radial at inlet and rotate at 320 revs per min. The blades occupy 6% of the circumferential area and are shaped to ensure that the radial velocity u1R is kept constant and equal to

0.2√2gh . If the shaft power is 75% of the water power, determine the:

(i) guide vane angle;

(ii) blade exit angle;

(iii) water power;

(iv) diagram power;

(v) shaft power;

(vi) height of runner blade at inlet and outlet.

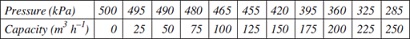

Question 4 A centrifugal pump has the following pressure - capacity characteristics:

It is planned to use this for a process having the following system characteristic:

(a) Determine the operating point for this pump with this system.

(b) The actual flowrate required by the process is 75 m3h-1. If the overall efficiency of the pump at this flowrate is 70%, determine the power consumed when the liquid being pumped has a density of 1250 kgm-3.

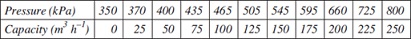

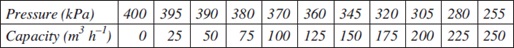

(c) A second pump is available which has the following characteristics:

For the same flowrate (75 m3h-1), this pump has an overall efficiency of 75%.

(i) Determine the power used by this pump at a flowrate of 75 m3h-1.

(ii) Would it be a better choice? Give reasons for your answer.

(iii) What other factors should be considered before a final choice is made?

Question 5 A process requires the precise control of the flow of a fluid to a reactor operating at 100 bar pressure (1 bar = 100 kPa). The flowrate may need to change to match the required reactor output. The flow should be relatively non-pulsating.

(a) Suggest a suitable pump for this duty. Give reasons for your choice.

(b) Describe, with the aid of a suitable diagram, the construction and operation of your chosen pump.

Question 6 It is proposed to pump 1600 m3 of a liquid (density 1100 kgm-3) each day through a total head of 12 m (including all losses) by using either a centrifugal or a reciprocating pump.

The centrifugal pump has a discharge rate of 1.8 m3min-1 when driven by an electric motor supplying a power of 4.75 kW.

The reciprocating pump discharges 2.0 m3min-1 when driven by an electric motor supplying 5 kW.

(a) Calculate the efficiency of each pump.

(b) If electricity costs 16p per kWh, select the most economical pump and determine the cost saving over 100 days of operation.

(c) State two other factors which should be considered before a final choice of pump is made.